Custom Printed Food Grade Stand Up Pouches with zipper

Custom stand up pouches looks professional and with a lot of features you can add on to make your brands more attractive.The printed package is brilliant in sales and brand promotion. General Information.

| MOQ | 100 Pcs -digital printing10,000 pcs -roto gravure printing |

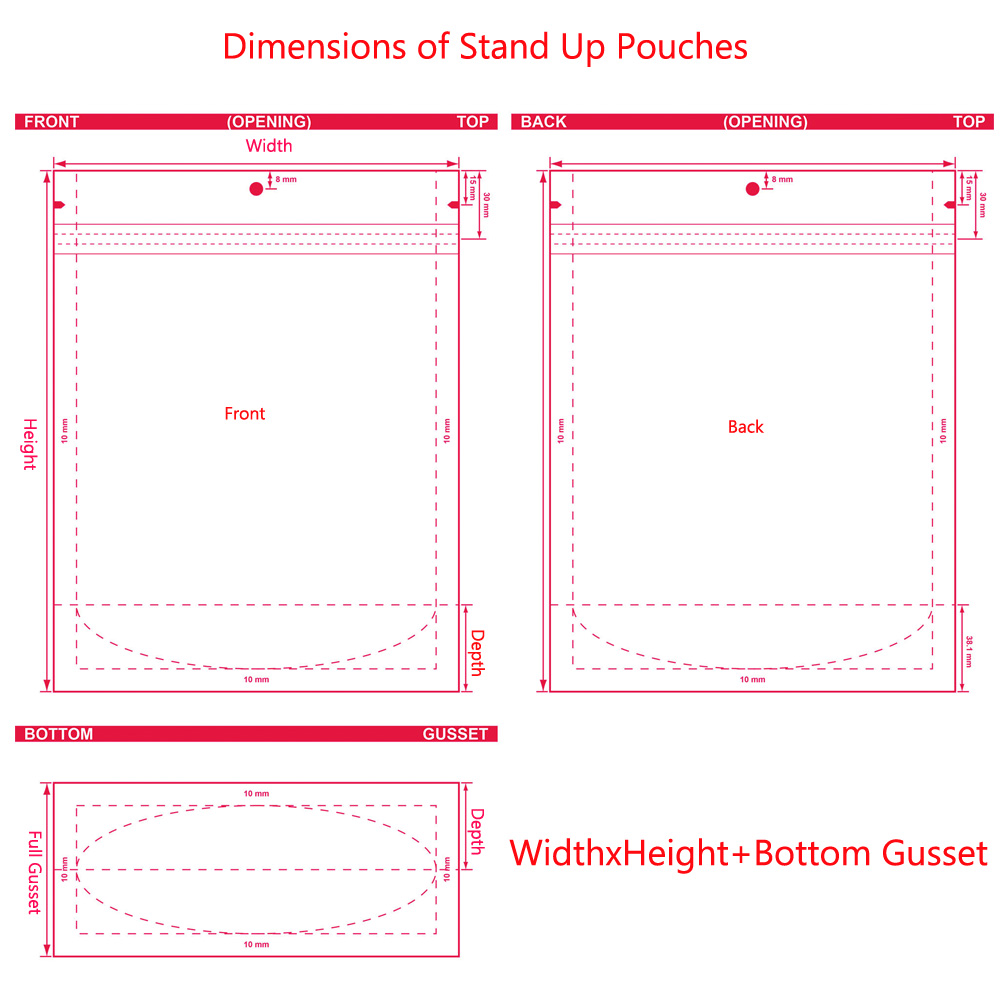

| Sizes | Custom , Refer to standard dimensions |

| Material | Up to the product and volume of packaging |

| Thickness | 50-200 microns |

| Features of pouches | Hanger Hole, Rounded Corner, Tear Notches, Zipper,Spot Embellishments,Transparent Or Clouded Windows |

Take advantages of standing up pouches ,can make our daily life easier. Doypack is popular in packaging products in wide range.

• Ground Coffee And Loose-Leaf Tea . Perfect packaging with multi-layer to keep coffee beans and tea from dust and humidity.

• Baby Food. Stand up pouch keep food clean and hygeian.Make baby food a ready-to-go solution for activities outside.

• Sweets And Snacks Packaging. Stand up pouch is cost-effective packaging option for light weight candies.Sturdy enough not to rip, while also allowing effortless handling and reliable resealing.

• Food Supplements Packaging.Stand-up pouches are safeguard for healthy food packaging, such as supplements,protein powder.Long-shelf life and nutrition protection.

• Pet Treats And Wet Food.More convenient than metal cans.Good option for both pet food manufacture and consumers.Easy to carry when walk with pets.Easily resealed to preserve the freshness of the contents and reduce wastage.

• Household Products & Essentials. Stand up pouches are suitable for non-food items.As facial masks, washing gel and powder ,liquid,bath salts. Versatile solution for your products.Resealable pouches work as refill packs.Encourage consumers to refill their bottles at home-saving waste of single use of plastic.

Standard Dimensions of Stand Up Pouches

| 1oz | Height x Width x Gusset: 5-1/8 x 3-1/4 x 1-1/2 inches 130 x 80 x 40 mm |

| 2oz | 6-3/4 x 4 x 2 inches 170 x 100 x 50 mm |

| 3oz | 7 in x 5 in x 1-3/4 in 180 mm x 125 mm x 45 mm |

| 4oz | 8 x 5-1/8 x 3 inches 205 x 130 x 76 mm |

| 5oz | 8-1/4 x 6-1/8 x 3-3/8 inches 210 x 155 x 80 mm |

| 8oz | 9 x 6 x 3-1/2 inches 230 x 150 x 90 mm |

| 10oz | 10-7/16 x 6-1/2 x 3-3/4 inches 265 x 165 x 96 mm |

| 12oz | 11-1/2 x 6-1/2 x 3-1/2 inches 292 x 165 x 85 mm |

| 16oz | 11-3/8 x 7-1/16 x 3-15/16 inches 300 x 185 x 100 mm |

| 500g | 11-5/8 x 8-1/2 x 3-7/8 inches 295 x 215 x 94 mm |

| 2lb | 13-3/8 inches x 9-3/4 inches x 4-1/2 inches 340 mm x 235 mm x 116 mm |

| 1kg | 13-1/8 x 10 x 4-3/4 inches 333 x 280 x 120 mm |

| 4lb | 15-3/4 inches x 11-3/4 inches x 5-3/8 inches 400 mm x 300 mm x 140 mm |

| 5lb | 19 inches x 12-1/4 inches x 5-1/2 inches 480 mm x 310 mm x 140 mm |

| 8lb | 17-9/16 inches x 13-7/8 inches x 5-3/4 inches 446 mm x 352 mm x 146 mm |

| 10lb | 17-9/16 inches x 13-7/8 inches x 5-3/4 inches 446 mm x 352 mm x 146 mm |

| 12lb | 21-1/2 inches x 15-1/2 inches x 5-1/2 inches 546 mm x 380 mm x 139 mm |

Regarding CMYK Printing

• White Ink: Need a white color plate for transparent clear film when print.Please note that white ink is not 100% Opaque.

• Spot colors: Mostly used for lines and large solid area.Must be designated with STANDARD Pan-tone Matching System (PMS).

Placement Guidelines

Avoid placing critical graphics in the following areas:

-zipper area

-seal zones

-around hanger hole

-Travel and Variation: Production features such as image placement and feature location have a tolerance and can TRAVEL. Refer to following tablet.

| Length (mm) | Tolerance of L(mm) | Tolerance of W(mm) | Tolerance of Sealing Area(mm) |

| <100 | ±2 | ±2 | ±20% |

| 100~400 | ±4 | ±4 | ±20% |

| ≥400 | ±6 | ±6 | ±20% |

| Average thickness tolerance ±10% (um) | |||

File Format & Graphics Handling

•Please make art in Adobe Illustrator.

•Vector editable line art for all text ,elements and graphics.

•Please do not create traps.

•Please outline all type.

•Including all effects notes.

•Photographs / Images MUST be 300 dpi

•If including photographs / images that can be assigned a Pan-tone color: Use a placed background gray-scale or PMS Duo-tone.

•Use Pan-tone colors if applicable.

•Keep vector elements in illustrator

Proofing

-PDF or .JPG Proofs are used for layout confirmation. Color display differently on each monitor and will NOT be used for color matching.

-For spot ink color evaluation should refer to Pantone color book.

-Final color can be affected by material structure, and printing ,lamination ,varnish process.

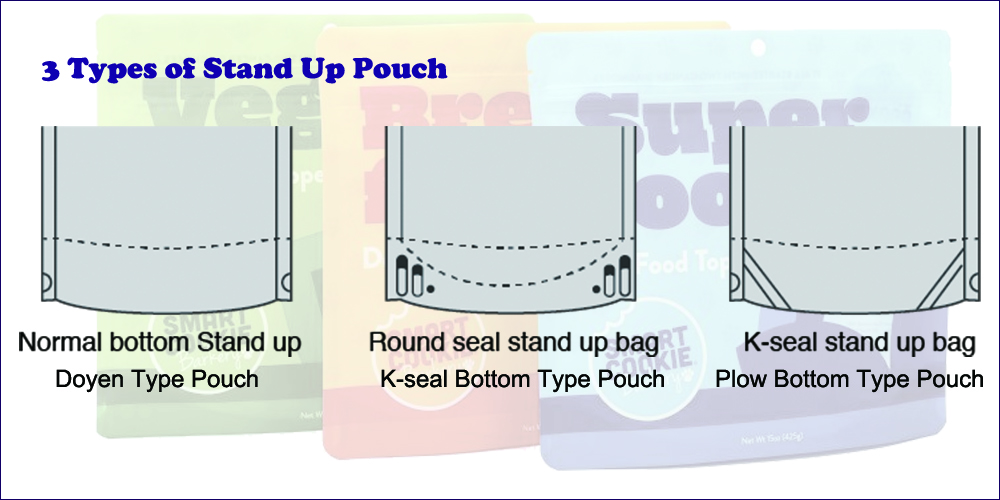

3 Types of Stand Up Pouch

There are basically three kinds of stand up pouches.

| Item | Difference | Suitable weight |

| 1.Doyen, also called round bottom gusset pouch or Doypack

|

Sealing area differs |

lightweight products (less than one pound). |

| 2.K-seal Bottom | between 1 pound and 5 pounds | |

| 3.Plow bottom doypack | heavier than 5 pounds |

All the suggestions above on weight based on our experience.For the specific bags, please confirm with our sales team or ask for free samples for test.

FAQ

1.how do you seal a stand up pouch.

Press the zipper and seal the pouch. There are press-and-close zip enclosed .

2.How much will a stand up pouch hold.

It depends on the dimensions of the pouch and the shape or density of the product. 1kg grains, beans,powder and liquid, cookies use different sizes.Need to test the sample bag and decide.

3.What are stand up pouches made of.

1) food grade material. FDA approved and is safe for direct contact with food.

2) Laminated films. Normally LLDPE linear low-density polyethylen inside to contact food directly. Polyester, Orientated Polypropylene Film,BOPA Film,evoh, paper, vmpet, aluminum foil, Kpet, KOPP.

4.what is the different types of pouches.

The are a wide variety of pouches.Flat pouches ,side gusset pouches, flat bottom bags, shaped bags,variations,quad seal bags.