Frozen Spinach Pouch for Fruits and Vegetables packaging

Quick Product Detail

|

Bag Style: |

Frozen berry packaging Stand up bags with zip |

Material Lamination: |

PET/AL/PE, PET/AL/PE, OPP/VMPET/LDPE PET/VMPET/PE PET/PE,PA/LDPE |

|

Brand : |

PACKMIC,OEM &ODM |

Industrial Usage: |

Frozen fruits and vegetables packaging purpose |

|

Place of origin |

Shanghai, China |

Printing: |

Gravure Printing |

|

Color: |

CMYK+Spot color |

Size/Design/logo: |

Customized |

|

Feature: |

Barrier, Moisture Proof,reusable, frozen/freezing packaging |

Sealing &Handle: |

Heat sealing, zip sealed, |

Customized Options

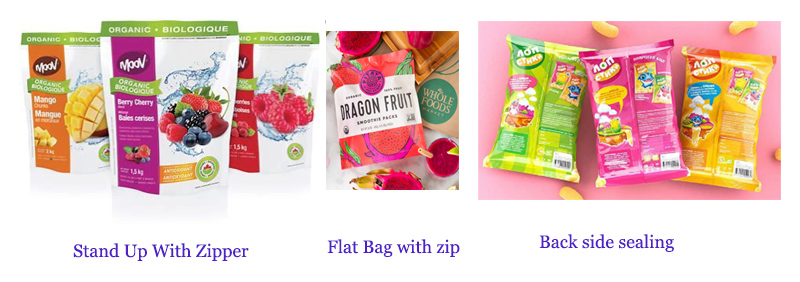

Bag type: Stand up pouches with zip , flat bag with zip, back sealing pouch

Requirements For Printed Fruits And Vegetables Packaging Bag With Zip

When creating printed packaging bags with zippers for fruits and vegetables, several requirements need to be considered to ensure the bags are functional, safe, and appealing.

1. Material Selection for frozen food

● Barrier Properties: The material should have adequate moisture and oxygen barrier properties to keep produce fresh.

● Durability: The bag should withstand handling, stacking, and transportation without tearing.

● Food Safety: The materials must be food-grade and comply with safety regulations (e.g., FDA, EU standards).

● Biodegradability: Consider using biodegradable or compostable materials to reduce environmental impact.

2. Design and Printing

Visual Appeal: High-quality graphics and colors that attract consumers while clearly showcasing the contents.

Branding: Space for logos, brand names, and information that need to be clearly displayed.

Labeling: Include nutritional information, handling instructions, origin, and any relevant certifications (organic, non-GMO, etc.).

Clear Window: Consider incorporating a transparent section to allow visibility of the product.

3. Functionality for frozen packaging

Zipper Closure: A reliable zipper mechanism that allows for easy opening and resealing, keeping produce fresh and secure.

Size Variations: Offer different sizes to accommodate various types of fruits and vegetables.

Ventilation: Include perforations or breathable materials if necessary for products that require airflow (e.g., certain fruits).

4. Regulatory Compliance

Labeling Requirements: Ensure all information complies with local and international laws concerning food packaging.

Recyclability: Clearly indicate if the packaging is recyclable and the appropriate disposal methods.

5. Sustainability

Eco-friendly options: Consider materials that are sourced sustainably.

Reduced Plastic Use: Explore the use of less plastic or alternative materials to minimize environmental footprint.

6. Cost-Effectiveness

Production Cost: Balance quality with cost to ensure the bags are economically viable for producers and retailers.

Bulk Production: Consider the feasibility of printing and producing in bulk to lower costs.

7. Testing and Quality Assurance

Seal Integrity: Conduct tests to ensure the zipper seals effectively and maintains freshness.

Shelf-life Testing: Evaluate how well the packaging extends the shelf life of the fruits and vegetables.

When designing printed packaging bags with zippers for fruits and vegetables, it is crucial to prioritize food safety, functionality, aesthetic appeal, and sustainability. Ensuring compliance with regulations and testing the final product will lead to successful packaging solutions that meet consumer needs while protecting produce quality.

Supply Ability

400,000 Pieces per Week

Packing & Delivery

Packing: normal standard export packing,500-3000pcs in a carton;

Delivery Port: Shanghai, Ningbo, Guangzhou port, any port in China;

Leading Time

| Quantity(Pieces) | 1-30,000 | >30000 |

| Est. Time(days) | 12-16days | To be negotiated |

FAQ for R&D

Q1:Can you products made with customer’s logo?

Yes, of course we can offer OEM/ODM, provide the logo customized for free.

Q2:How often your products get updated?

We pay more attention to our products every year on R&D our products, and 2-5 kinds of new design will come up each year, we always complete our products based on our customer’s feedback.

Q3:What are the technical indicators of your products? If so, what are the specific ones?

Our company has clear technical indicators, the technical indicators of flexible packaging include: material thickness, food grade ink, etc.

Q4:Can your company identify your own products?

Our products are easily distinguished from other brand products in terms of appearance, material thickness and surface finish. Our products have great advantages in aesthetics and durability.