Lub hnab ntim Retort tau pib los ntawm kev tshawb fawb thiab kev tsim cov kaus poom mos hauv nruab nrab-20th caug xyoo. Cov kaus poom muag muag yog hais txog cov ntim khoom uas ua los ntawm cov khoom muag muag lossis cov thawv ntim ib nrab uas tsawg kawg yog ib feem ntawm phab ntsa lossis lub thawv npog yog ua los ntawm cov khoom ntim mos, nrog rau cov hnab ntim retort, retort lub thawv, khi cov hnyuv ntxwm, thiab lwm yam. Daim ntawv tseem ceeb tam sim no siv yog prefabricated high-temperature retort hnab. Piv nrog cov hlau tsoos, iav thiab lwm cov kaus poom tawv, cov hnab ntim khoom muaj cov yam ntxwv hauv qab no:

● Lub thickness ntawm cov khoom ntim yog me me, thiab lub tshav kub hloov tau ceev, uas tuaj yeem txo lub sijhawm kom tsis muaj menyuam. Yog li ntawd, cov xim, aroma thiab saj ntawm cov ntsiab lus hloov me ntsis, thiab qhov poob ntawm cov as-ham yog me me.

● Cov khoom ntim yog lub teeb hauv qhov hnyav thiab me me, uas tuaj yeem txuag cov ntaub ntawv ntim khoom, thiab cov nqi tsheb thauj mus los tsawg thiab yooj yim.

● Tau luam cov qauv zoo heev.

●Nws muaj lub neej txee ntev (6-12 lub hlis) ntawm chav tsev kub thiab yooj yim kaw thiab qhib.

● Tsis tas yuav tsum muaj lub tub yees, txuag cov nqi tub yees

● Nws yog tsim rau ntim ntau yam khoom noj, xws li nqaij thiab nqaij qaib, cov khoom siv dej, txiv hmab txiv ntoo thiab zaub, ntau yam khoom noj khoom haus, thiab kua zaub.

●Nws tuaj yeem ua kom sov ua ke nrog lub pob kom tiv thaiv kom tsis txhob poob, tshwj xeeb tshaj yog haum rau kev ua haujlwm, mus ncig, thiab khoom noj tub rog.

Ua tiav lub hnab ntim khoom noj, suav nrog cov ntsiab lus, kev lees paub zoo ntawm kev nkag siab zoo ntawm cov khoom tsim qauv, substrate thiab number case, adhesive xaiv, txheej txheem tsim khoom, kuaj cov khoom, ntim thiab sterilization txheej txheem tswj, thiab lwm yam, vim yog lub hnab ntim khoom tsim qauv yog qhov tseem ceeb, yog li qhov no yog kev tsom xam dav dav, tsis tsuas yog txhawm rau txheeb xyuas qhov sib txawv ntawm cov khoom thiab cov khoom sib txawv. Cov khoom siv, kev siv, Kev Nyab Xeeb thiab kev nyiam huv, kev lag luam thiab lwm yam.

1. Zaub Mov Spoilage Thiab Sterilization

Tib neeg nyob hauv cov kab mob microbial ib puag ncig, tag nrho lub ntiaj teb biosphere muaj nyob rau hauv suav tsis txheeb cov kab mob, cov zaub mov hauv microbial reproduction ntau tshaj li ib qho kev txwv, cov zaub mov yuav lwj thiab poob ntawm edibility.

Ua rau cov zaub mov lwj ntawm cov kab mob feem ntau yog pseudomonas, vibrio, ob qho tib si kub-resistant, enterobacteria ntawm 60 ℃ cua sov rau 30 feeb yog tuag, lactobacilli qee hom tuaj yeem tiv taus 65 ℃, 30 feeb ntawm cua sov. Bacillus feem ntau tuaj yeem tiv taus 95-100 ℃, cua sov rau ob peb feeb, ob peb tuaj yeem tiv taus 120 ℃ hauv qab 20 feeb ntawm cua sov. Ntxiv nrog rau cov kab mob, kuj tseem muaj cov kab mob loj hauv cov zaub mov, suav nrog Trichoderma, poov xab thiab lwm yam. Tsis tas li ntawd, lub teeb, oxygen, qhov kub thiab txias, noo noo, PH tus nqi thiab lwm yam tuaj yeem ua rau cov zaub mov tsis zoo, tab sis lub ntsiab tseem ceeb yog cov kab mob, yog li ntawd, kev siv cov khoom kub kub los tua cov kab mob yog ib qho tseem ceeb ntawm kev khaws zaub mov kom ntev.

Sterilization ntawm cov khoom noj khoom haus yuav muab faib ua 72 ℃ pasteurization, 100 ℃ boiling sterilization, 121 ℃ high-temperature ua noj sterilization, 135 ℃ high-temperature cook sterilization thiab 145 ℃ ultra-high-temperature instantaneous sterilization, as well as some manufacturers siv non-standard sterilization. Raws li cov khoom sib txawv los xaiv cov kev ua kom tsis muaj menyuam, qhov nyuaj tshaj plaws los tua cov kab mob kom tsis muaj menyuam ntawm Clostridium botulinum yog qhia hauv Table 1.

Table 1 Lub sij hawm ntawm kev tuag ntawm Clostridium botulinum spores nyob rau hauv relation to kub

| kub ℃ | 100 | 105 | 110 | 115 | 120 | 125 | 130 | 135 |

| Lub sij hawm tuag (feeb) | 330 | 100 | 32 | 10 | 4 | 80s ib | 30s | 10s |

2.Steamer Bag Raw Khoom yam ntxwv

High kub ua noj retort hnab hnab tuaj nrog cov khoom hauv qab no:

Kev ntim khoom ntev ntev, ruaj khov cia, tiv thaiv kab mob kev loj hlob, kub tsis muaj zog tiv thaiv, thiab lwm yam.

Nws yog ib qho khoom siv zoo heev uas haum rau kev ntim khoom noj tam sim.

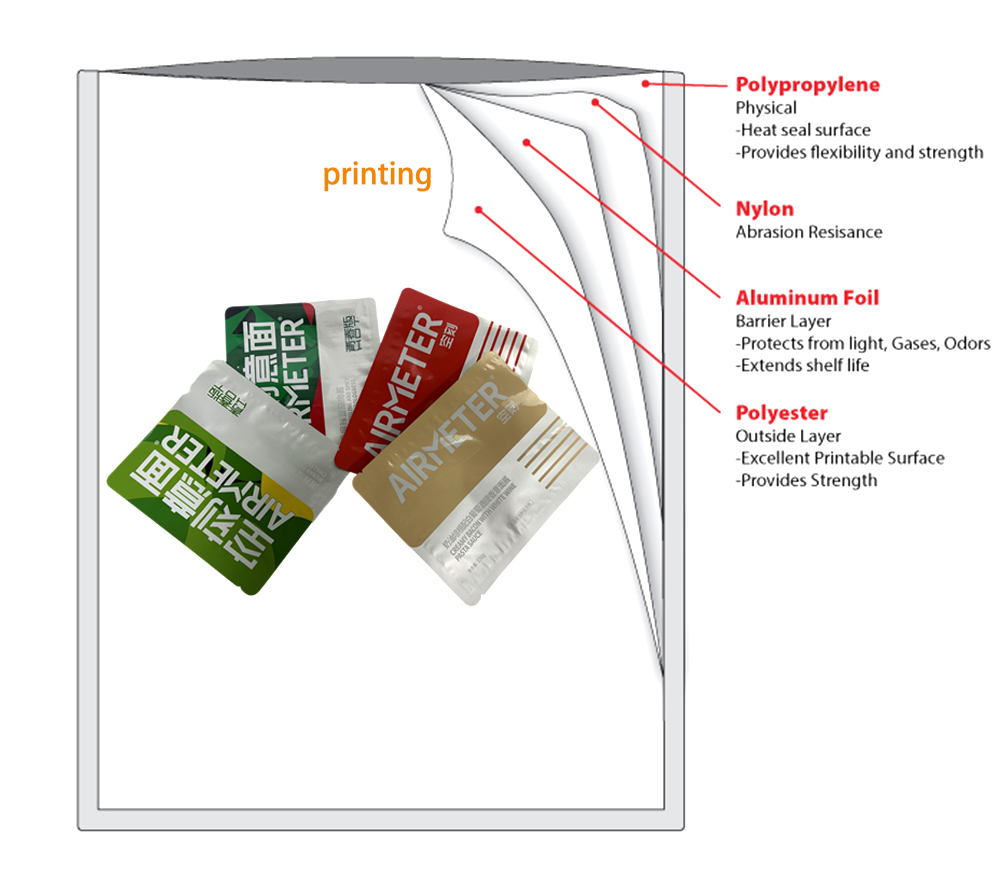

Cov qauv kuaj PET / nplaum / aluminium ntawv ci / nplaum nplaum / nylon / RCPP

High-temperature retorting hnab nrog peb txheej qauv PET / AL / RCPP

COV TSWV YIM

(1) PET zaj duab xis

BOPET zaj duab xis muaj ib qho ntawmqhov siab tshaj tensile zogntawm tag nrho cov yas zaj duab xis, thiab tuaj yeem ua tau raws li qhov xav tau ntawm cov khoom nyias nyias nrog siab rigidity thiab hardness.

Zoo heev txias thiab kub tsis kam.Qhov ntsuas kub ntawm BOPET zaj duab xis yog los ntawm 70 ℃ - 150 ℃, uas tuaj yeem tswj xyuas lub cev zoo hauv qhov kub thiab txias thiab haum rau feem ntau ntawm cov khoom ntim.

Barrier kev ua tau zoo heev.Nws muaj kev ua tau zoo ntawm dej thiab huab cua thaiv kev ua haujlwm, tsis zoo li nylon uas cuam tshuam zoo heev los ntawm cov av noo, nws cov dej tsis kam zoo ib yam li PE, thiab nws cov huab cua permeability coefficient tsawg heev. Nws muaj cov cuab yeej tiv thaiv siab heev rau huab cua thiab tsw, thiab yog ib qho ntawm cov ntaub ntawv khaws cov tshuaj tsw qab.

Tshuaj tiv thaiv, tiv taus roj thiab roj, feem ntau cov kuab tshuaj thiab dilute acids thiab alkalis.

(2) PEB FILM

BOPA cov yeeb yaj kiab muaj qhov toughness zoo heev.Lub zog tensile, lub zog tsim kua muag, cuam tshuam lub zog thiab lub zog tawg yog qhov zoo tshaj plaws hauv cov ntaub ntawv yas.

Kev ua tau zoo tshaj plaws, pinhole tsis kam, tsis yooj yim rau cov ntsiab lus ntawm qhov sib tsoo, yog ib qho tseem ceeb ntawm BOPA, zoo elasticity, tab sis kuj ua rau lub ntim zoo.

Kev tiv thaiv zoo, muaj ntxhiab tsw zoo, tiv thaiv cov tshuaj tsis muaj zog acids, tshwj xeeb tshaj yog cov roj ua haujlwm zoo.

Nrog rau ntau yam kev khiav hauj lwm kub thiab lub melting point ntawm 225 ° C, nws yuav siv tau rau lub sij hawm ntev ntawm -60 ° C thiab 130 ° C. Cov khoom siv kho tshuab ntawm BOPA tau khaws cia ntawm qhov kub thiab txias.

Qhov kev ua tau zoo ntawm BOPA zaj duab xis cuam tshuam zoo heev los ntawm cov av noo, thiab ob qho tib si kev ruaj ntseg thiab cov khoom thaiv kev cuam tshuam los ntawm cov av noo.Tom qab BOPA zaj duab xis raug rau cov dej noo, ntxiv rau qhov wrinkling, feem ntau nws yuav elongate horizontally. Longitudinal shortening, elongation tus nqi txog li 1%.

(3) CPP zaj duab xis polypropylene zaj duab xis, kub tsis kam, zoo kub sealing kev ua tau zoo;

CPP zaj duab xis uas yog cam khwb cia polypropylene zaj duab xis, CPP zaj duab xis dav dav siv binary random copolypropylene raw cov ntaub ntawv, lub hnab zaj duab xis ua los ntawm 121-125 ℃ high-temperature sterilization tuaj yeem tiv taus 30-60 feeb.

CPP high-temperature ua noj zaj duab xis siv thaiv copolypropylene raw cov ntaub ntawv, ua los ntawm cov hnab zaj duab xis tuaj yeem tiv taus 135 ℃ kub sterilization, 30 feeb.

Kev ua tau zoo yuav tsum yog: Vicat softening point kub yuav tsum siab tshaj qhov kub ua noj, qhov cuam tshuam kuj yuav tsum yog qhov zoo, kev tshaj tawm tsis zoo, ntses-qhov muag thiab crystal point yuav tsum tsawg li sai tau.

Muaj peev xwm tiv taus 121 ℃ 0.15Mpa siab ua kom tsis muaj menyuam, yuav luag tuav cov khoom noj, tsw, thiab zaj duab xis yuav tsis tawg, tev, los yog adhesion, muaj kev ruaj ntseg zoo; feem ntau nrog nylon zaj duab xis los yog polyester zaj duab xis composite, ntim cov kua zaub hom zaub mov, raws li zoo raws li meatballs, dumplings, mov, thiab lwm yam khoom noj khov.

(4) Aluminium Ntawv Nyiaj

Aluminium ntawv ci yog tib daim ntawv hlau hauv cov ntaub ntawv ntim khoom yooj yim, aluminium ntawv ci yog cov khoom siv hlau, nws cov dej thaiv, roj thaiv, lub teeb thaiv, tsw tuav yog lwm yam khoom siv pob khoom nyuaj sib piv. Aluminium ntawv ci yog tib daim ntawv hlau hauv cov ntaub ntawv ntim tau yooj yim. Muaj peev xwm tiv taus 121 ℃ 0.15Mpa siab ua kom tsis muaj menyuam, kom paub meej cov khoom noj, tsw, thiab zaj duab xis yuav tsis tawg, tev, lossis adhesion, muaj kev ruaj ntseg zoo; feem ntau nrog nylon zaj duab xis los yog polyester zaj duab xis composite, ntim cov khoom noj uas muaj kua zaub, thiab nqaij npuas, dumplings, mov thiab lwm yam khoom noj khov.

(5) IB

Steamer hnab siv polyurethane-raws li number case rau luam ntawv, qhov yuav tsum tau ntawm cov residual kuab tshuaj uas tsis muaj cov kuab tshuaj, siab composite zog, tsis muaj discoloration tom qab ua noj, tsis muaj delamination, wrinkles, xws li ua noj kub tshaj 121 ℃, ib tug tej feem ntawm hardener yuav tsum tau muab ntxiv los ua kom cov kub tsis kam ntawm tus number case.

Kev huv huv ntawm tus number case yog qhov tseem ceeb heev, cov hlau hnyav xws li cadmium, txhuas, mercury, chromium, arsenic thiab lwm yam hlau hnyav tuaj yeem ua rau muaj kev phom sij loj rau lub ntuj thiab tib neeg lub cev. Thib ob, tus number case nws tus kheej yog cov khoom siv, tus number case ntau qhov sib txuas, pigments, dyes, ntau yam additives, xws li defoaming, antistatic, plasticizers thiab lwm yam kev nyab xeeb. Yuav tsum tsis txhob pub ntxiv ntau yam xim hlau hnyav, glycol ether thiab ester compounds. Cov kuab tshuaj yuav muaj benzene, formaldehyde, methanol, phenol, linkers yuav muaj dawb toluene diisocyanate, pigments yuav muaj PCBs, aromatic amines thiab hais txog.

(6) Adhesives

Steamer Retorting hnab sib xyaw siv ob lub ntsiab lus polyurethane nplaum, tus neeg sawv cev tseem ceeb muaj peb yam: polyester polyol, polyether polyol, polyurethane polyol. Muaj ob hom tshuaj tua kab mob: muaj ntxhiab polyisocyanate thiab aliphatic polyisocyanate. Qhov zoo dua kub resistant steaming nplaum muaj cov yam ntxwv hauv qab no:

●High solids, low viscosity, good spreadability.

● Zoo heev pib adhesion, tsis poob ntawm tev lub zog tom qab steaming, tsis muaj tunneling nyob rau hauv ntau lawm, tsis wrinkling tom qab steaming.

● Cov nplaum muaj kev nyab xeeb, tsis muaj tshuaj lom thiab tsis muaj ntxhiab.

● Cov tshuaj tiv thaiv sai dua thiab lub sijhawm luv luv (hauv 48 teev rau cov khoom siv yas-yas sib xyaw thiab 72 teev rau cov khoom siv txhuas-yas sib xyaw).

● Tsawg txheej ntim, muaj zog sib txuas, siab kub sealing zog, zoo kub kuj.

● Tsawg dilution viscosity, tuaj yeem ua haujlwm siab hauv lub xeev, thiab kev sib kis tau zoo.

● Ntau yam ntawm daim ntawv thov, haum rau ntau yam yeeb yaj kiab.

● Zoo tiv thaiv tsis kam (kub, Frost, acid, alkali, ntsev, roj, ntsim, thiab lwm yam).

Kev tu cev ntawm cov nplaum yog pib nrog kev tsim cov thawj aromatic amine PAA (primary aromatic amine), uas yog los ntawm cov tshuaj lom neeg cov tshuaj tiv thaiv ntawm aromatic isocyanates thiab dej nyob rau hauv luam ntawv ob-tivthaiv inks thiab laminating adhesives.Qhov tsim ntawm PAA yog muab tau los ntawm aromatic isocyanates, tab sis tsis yog los ntawm alidhoxyes-based acrylics. muaj cov khoom tsis tiav, cov khoom tsis muaj molecular thiab cov kuab tshuaj residual tuaj yeem ua rau muaj kev phom sij. Lub xub ntiag ntawm cov tsis tiav cov molecules tsawg thiab cov kuab tshuaj seem tuaj yeem ua rau muaj kev phom sij.

3.Cov qauv tseem ceeb ntawm lub hnab ua noj

Raws li kev lag luam thiab lub cev thiab cov khoom siv tshuaj lom neeg ntawm cov khoom siv, cov qauv hauv qab no feem ntau siv rau cov hnab ntim khoom noj.

Ob txheej: PET / CPP, BOPA / CPP, GL-PET / CPP.

Peb txheej: PET / AL / CPP, BOPA / AL / CPP, PET / BOPA / CPP,

GL-PET / BOPA / CPP, PET / PVDC / CPP, PET / EVOH / CPP, BOPA / EVOH / CPP

Plaub txheej: PET / PA / AL / CPP, PET / AL / PA / CPP

Multi-storey qauv.

PET / EVOH coextruded zaj duab xis / CPP, PET / PVDC coextruded zaj duab xis / CPP, PA / PVDC coextruded zaj duab xis / CPP tus tsiaj / EVOH coextruded zaj duab xis, PA / PVDC coextruded zaj duab xis

4. Kev tshuaj xyuas cov yam ntxwv ntawm lub hnab ua noj

Cov qauv yooj yim ntawm lub hnab ua noj ua haus muaj txheej txheej txheej / nruab nrab txheej / cua sov txheej txheej. Cov txheej txheej saum npoo feem ntau yog ua los ntawm PET thiab BOPA, uas ua lub luag haujlwm ntawm kev txhawb nqa lub zog, tiv thaiv tshav kub thiab luam ntawv zoo. Cov txheej txheem nruab nrab yog ua los ntawm Al, PVDC, EVOH, BOPA, uas tsuas yog ua lub luag haujlwm ntawm kev thaiv, thaiv lub teeb, ob sab sib xyaw, thiab lwm yam. Lub tshav kub sealing txheej yog ua los ntawm ntau hom CPP, EVOH, BOPA, thiab lwm yam. Thaum tshav kub kub sealing txheej xaiv ntawm ntau hom CPP, co-extruded PP thiab PVDC, EVOH co-extruded zaj duab xis, 110 ℃ hauv qab ua noj kuj yuav tsum tau xaiv LLDPE zaj duab xis, feem ntau ua si lub luag hauj lwm nyob rau hauv tshav kub sealing, puncture kuj, tshuaj tsis kam, tab sis kuj tsis tshua muaj adsorption ntawm cov khoom, kev tu cev yog zoo.

4.1 PET / kua nplaum / PE

Cov qauv no tuaj yeem hloov pauv mus rau PA / kua nplaum / PE, PE tuaj yeem hloov mus rau HDPE, LLDPE, MPE, ntxiv rau qee qhov tshwj xeeb HDPE zaj duab xis, vim qhov kub tsis kam los ntawm PE, feem ntau siv rau 100 ~ 110 ℃ lossis yog li cov hnab ntim tsis muaj menyuam; kua nplaum tuaj yeem raug xaiv los ntawm cov kua nplaum zoo tib yam polyurethane thiab cov kua nplaum ua kua nplaum, tsis haum rau cov nqaij ntim khoom, qhov thaiv tsis zoo, lub hnab yuav wrinkled tom qab steaming, thiab qee zaum cov txheej txheej ntawm zaj duab xis lo rau ib leeg. Qhov tseem ceeb, cov qauv no tsuas yog ib lub hnab boiled los yog pasteurized hnab.

4.2 PET / kua nplaum / CPP

Cov qauv no yog cov qauv pob tshab pob tshab ua noj ua haus, tuaj yeem ntim tau feem ntau ntawm cov khoom ua noj, uas yog tus cwj pwm los ntawm kev pom ntawm cov khoom, koj tuaj yeem pom cov ntsiab lus ncaj qha, tab sis tsis tuaj yeem ntim tau yuav tsum zam lub teeb ntawm cov khoom. Cov khoom yog ib qho nyuaj rau qhov kov, feem ntau yuav tsum tau xuas nrig ntaus cov ces kaum. Cov qauv ntawm cov khoom no feem ntau yog 121 ℃ sterilization, zoo tib yam high-temperature ua kua nplaum, zoo tib yam qib ua noj CPP yuav ua tau. Txawm li cas los xij, cov kua nplaum yuav tsum xaiv qhov qis me me ntawm cov qib, txwv tsis pub qhov kev cog lus ntawm cov kua nplaum yuav tsav cov number case txav mus, muaj peev xwm delamination tom qab steaming.

4.3 BOPA / kua nplaum / CPP

Qhov no yog ib lub hnab pob tshab ua noj rau 121 ℃ ua noj kom tsis muaj menyuam, zoo pob tshab, mos kov, zoo puncture kuj. Cov khoom siv kuj tsis tuaj yeem siv rau qhov xav tau kom tsis txhob muaj lub teeb ntim khoom.

Vim BOPA ya raws permeability loj, muaj cov khoom luam tawm nyob rau hauv steaming yooj yim los tsim cov xim permeability tshwm sim, tshwj xeeb tshaj yog cov liab series ntawm number case nkag mus rau saum npoo, ntau lawm tus number case feem ntau yuav tsum tau ntxiv ib tug curing agent los tiv thaiv. Tsis tas li ntawd, vim yog tus cwj mem nyob rau hauv BOPA thaum lub adhesion yog tsawg, tab sis kuj yooj yim los tsim anti-stick phenomenon, tshwj xeeb tshaj yog nyob rau hauv high humidity ib puag ncig. Semi-tiav cov khoom thiab cov hnab tiav hauv kev ua tiav yuav tsum tau muab kaw thiab ntim.

4.4 KPET/CPP, KBOPA/CPP

Cov qauv no tsis yog feem ntau siv, cov khoom pob tshab yog qhov zoo, nrog cov khoom muaj kev cuam tshuam siab, tab sis tsuas yog siv tau rau kev ua kom tsis muaj menyuam hauv qab 115 ℃, qhov kub tsis kam yog me ntsis zuj zus, thiab muaj kev tsis ntseeg txog nws txoj kev noj qab haus huv thiab kev nyab xeeb.

4.5 PET/BOPA/CPP

Cov qauv ntawm cov khoom no yog siab zog, zoo transparency, zoo puncture kuj, vim PET, BOPA shrinkage tus nqi sib txawv yog loj, feem ntau siv rau 121 ℃ thiab hauv qab cov khoom ntim.

Cov ntsiab lus ntawm lub pob yog ntau acidic lossis alkaline thaum xaiv cov qauv ntawm cov khoom, tsis yog siv cov qauv uas muaj txhuas.

Cov txheej txheej ntawm cov kua nplaum tuaj yeem siv los xaiv cov kua nplaum nplaum, tus nqi yuav raug txo kom tsim nyog.

4.6 PET/Al/CPP

Qhov no yog cov qauv uas tsis yog-pob tshab feem ntau ua noj ua haus lub hnab, raws li qhov sib txawv inks, kua nplaum, CPP, ua noj kub ntawm 121 ~ 135 ℃ tuaj yeem siv rau hauv cov qauv no.

PET / ib tug cwj mem / kub-kub nplaum / Al7µm / high-temperature adhesive / CPP60µm qauv tuaj yeem ncav cuag 121 ℃ ua noj ua haus.

PET / Ob tug cwj mem / Kub-kub nplaum / Al9µm / High-temperature adhesive / High-temperature CPP70µm qauv tuaj yeem siab tshaj 121 ℃ ua noj kub, thiab cov cuab yeej thaiv tau nce, thiab lub txee lub neej ntev, uas tuaj yeem ua tau ntau tshaj li ib xyoos.

4.7 BOPA/Al/CPP

Cov qauv no zoo ib yam li cov qauv saum toj no 4.6, tab sis vim yog qhov nqus dej loj thiab qhov shrinkage ntawm BOPA, nws tsis haum rau kev ua noj ua haus kub siab tshaj 121 ℃, tab sis cov puncture kuj zoo dua, thiab nws tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm 121 ℃ ua noj.

4.8 PET/PVDC/CPP, BOPA/PVDC/CPP

Cov qauv ntawm cov khoom barrier no zoo heev, haum rau 121 ℃ thiab cov nram qab no kub ua noj sterilization, thiab oxygen muaj ib tug siab barrier yuav tsum tau ntawm cov khoom.

PVDC nyob rau hauv cov qauv saum toj no tuaj yeem hloov tau los ntawm EVOH, uas kuj muaj cov cuab yeej thaiv siab, tab sis nws cov cuab yeej thaiv kev txo qis pom tseeb thaum nws yog sterilized ntawm qhov kub thiab txias, thiab BOPA tsis tuaj yeem siv los ua cov txheej txheej saum npoo, txwv tsis pub cov cuab yeej barrier txo qis nrog qhov nce ntawm qhov kub thiab txias.

4.9 PET/Al/BOPA/CPP

Qhov no yog ib qho kev ua tau zoo ntawm cov hnab ua noj uas tuaj yeem ntim tau txhua yam khoom ua noj thiab tuaj yeem tiv taus qhov kub ntawm 121 txog 135 degrees Celsius.

Structure I: PET12µm / high-temperature adhesive / Al7µm / high-temperature adhesive / BOPA15µm / high-temperature adhesive / CPP60µm, cov qauv no muaj teeb meem zoo, zoo puncture resistance, zoo lub teeb-absorbing zog, thiab nws yog ib hom ntawm zoo heev lub hnab 121 ℃.

Qauv II: PET12µm / high-temperature adhesive / Al9µm / high-temperature adhesive / BOPA15µm / high-temperature adhesive / high-temperature CPP70µm, cov qauv no, ntxiv rau tag nrho cov kev ua tau zoo ntawm cov qauv I, muaj cov yam ntxwv ntawm 121 ℃ thiab siab tshaj qhov ua noj ua haus. Qauv III: PET / kua nplaum A / Al / kua nplaum B / BOPA / kua nplaum C / CPP, cov kua nplaum ntawm cov kua nplaum A yog 4g / ㎡, cov kua nplaum ntawm cov kua nplaum B yog 3g / ㎡, thiab cov kua nplaum ntawm cov kua nplaum C yog 5-6g / ㎡, uas tuaj yeem ua tau raws li qhov yuav tsum tau ua, thiab txo cov kua nplaum B uas tsim nyog.

Hauv lwm qhov xwm txheej, cov kua nplaum A thiab cov kua nplaum B yog ua los ntawm cov kua nplaum zoo dua qub, thiab cov kua nplaum C yog ua los ntawm cov kua nplaum uas tiv taus kub, uas tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm 121 ℃ boiling, thiab tib lub sij hawm txo tus nqi.

Qauv IV: PET / kua nplaum / BOPA / kua nplaum / Al / kua nplaum / CPP, cov qauv no yog BOPA hloov txoj haujlwm, tag nrho kev ua tau zoo ntawm cov khoom tsis tau hloov pauv, tab sis BOPA toughness, puncture resistance, siab composite zog thiab lwm yam zoo, tsis muab tag nrho cov kev ua si rau cov qauv no, yog li ntawd, daim ntawv thov ntawm kuj tsawg.

4.10 PET / Co-extruded CPP

Co-extruded CPP nyob rau hauv cov qauv no feem ntau yog hais txog 5-txheej thiab 7-txheej CPP nrog siab barrier zog, xws li:

PP / bonding txheej / EVOH / bonding txheej / PP;

PP / Bonding txheej / PA / Bonding txheej / PP;

PP / bonded txheej / PA / EVOH / PA / bonded txheej / PP, thiab lwm yam;

Yog li ntawd, daim ntawv thov ntawm co-extruded CPP tsub kom lub toughness ntawm cov khoom, txo qhov tawg ntawm tej pob khoom thaum lub sij hawm nqus tsev vacuuming, kev kub siab, thiab siab fluctuations, thiab ncua sij hawm khaws cia vim qhov kev txhim kho barrier zog.

Nyob rau hauv luv luv, cov qauv ntawm high-temperature ua noj hnab ntau yam, saum toj no tsuas yog ib qho kev soj ntsuam ua ntej ntawm ib co qauv, nrog rau kev tsim cov ntaub ntawv tshiab, cov technologies tshiab, yuav muaj ntau cov qauv tshiab, kom cov ntim ua noj muaj kev xaiv ntau dua.

Post lub sij hawm: Lub Xya hli ntuj-13-2024