Retort pouch bags originated from the research and development of soft cans in the mid-20th century. Soft cans refer to packaging made entirely of soft materials or semi-rigid containers in which at least part of the wall or container cover is made of soft packaging materials, including retort bags, retort boxes, tied sausages, etc. The main form currently used is prefabricated high-temperature retort bags. Compared with traditional metal, glass and other hard cans, retort bags have the following characteristics:

●The thickness of the packaging material is small, and the heat transfer is fast, which can shorten the sterilization time. Therefore, the color, aroma and taste of the contents change little, and the loss of nutrients is small.

●The packaging material is light in weight and small in size, which can save packaging materials, and the transportation cost is low and convenient.

●Can print exquisite patterns.

●It has a long shelf life (6-12 months) at room temperature and is easy to seal and open.

●No refrigeration required, saving on refrigeration costs

●It is suitable for packing many kinds of food, such as meat and poultry, aquatic products, fruits and vegetables, various cereal foods, and soups.

●It can be heated together with the package to prevent the flavor from being lost, especially suitable for field work, travel, and military food.

Complete cooking bag production, including the type of content, quality assurance of a comprehensive understanding of the product's structural design, substrate and ink, adhesive selection, production process, product testing, packaging and sterilization process control, etc., due to the cooking bag product structure design is the core, so this is a broad analysis, not only to analyze the product's substrate configuration, and also to further analyze the performance of different structural products, use, Safety and hygiene, economy and so on.

1. Food Spoilage And Sterilization

Human beings live in the microbial surroundings, the whole earth's biosphere exists in countless microorganisms, food in the microbial reproduction of more than a certain limit, the food will be spoiled and loss of edibility.

Cause food spoilage of common bacteria are pseudomonas, vibrio, both heat-resistant, enterobacteria at 60 ℃ heating for 30 minutes are dead, lactobacilli some species can withstand 65 ℃, 30 minutes of heating. Bacillus can generally withstand 95-100 ℃, heating for several minutes, a few can withstand 120 ℃ under 20 minutes of heating. In addition to bacteria, there are also a large number of fungi in food, including Trichoderma, yeast and so on. In addition, light, oxygen, temperature, moisture, PH value and so on can cause food spoilage, but the main factor is microorganisms, therefore, the use of high-temperature cooking to kill microorganisms is an important method of food preservation for a long time.

Sterilization of food products can be divided into 72 ℃ pasteurization, 100 ℃ boiling sterilization, 121 ℃ high-temperature cooking sterilization, 135 ℃ high-temperature cooking sterilization and 145 ℃ ultra-high-temperature instantaneous sterilization, as well as some manufacturers use non-standard temperature sterilization of about 110 ℃. According to the different products to choose the sterilization conditions, the most difficult to kill the sterilization conditions of Clostridium botulinum is shown in Table 1.

Table 1 Time of death of Clostridium botulinum spores in relation to temperature

| temperature℃ | 100 | 105 | 110 | 115 | 120 | 125 | 130 | 135 |

| Time of death (minutes) | 330 | 100 | 32 | 10 | 4 | 80s | 30s | 10s |

2.Steamer Bag Raw Material Characteristics

High temperature cooking retort pouch bags coming with the following properties:

Long-lasting packaging function, stable storage, prevention of bacterial growth, high temperature sterilization resistance, etc.

It is a very good composite material suitable for instant food packaging.

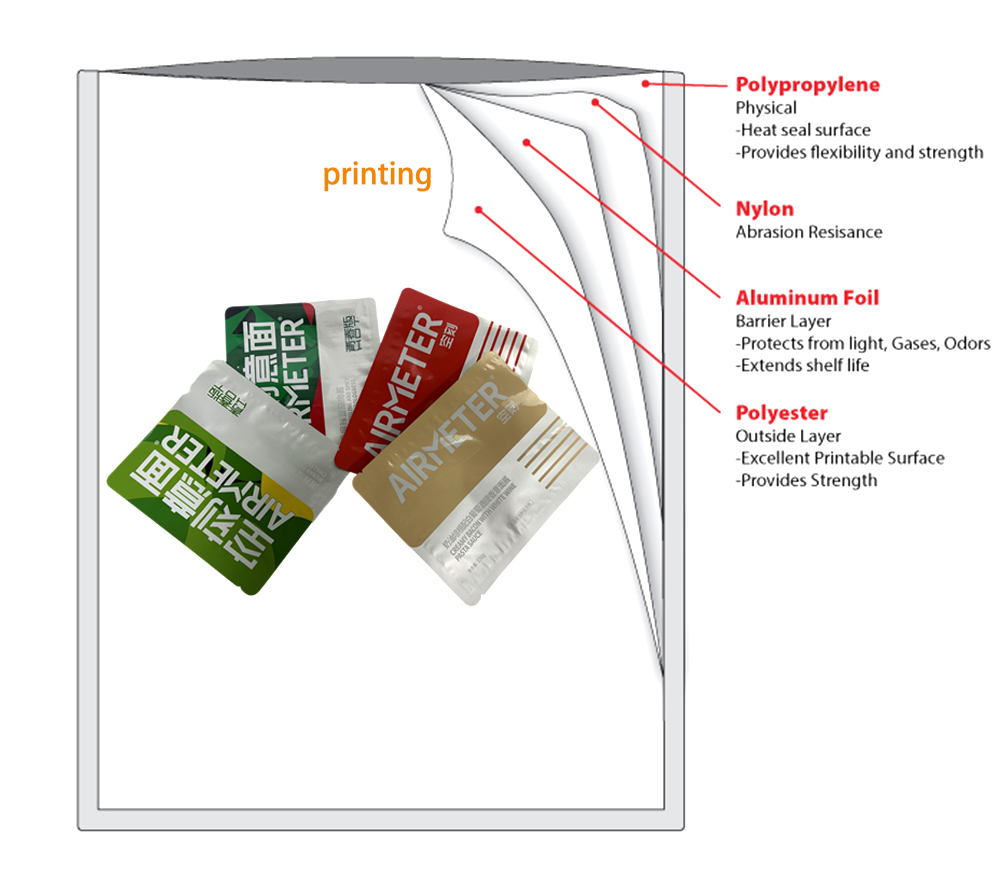

Typical structure test PET/adhesive/aluminum foil/adhesive glue/nylon/RCPP

High-temperature retorting bag with three-layer structure PET/AL/RCPP

MATERIAL INSTRUCTION

(1) PET film

BOPET film has one of the highest tensile strengths of all plastic films, and can meet the needs of very thin products with high rigidity and hardness.

Excellent cold and heat resistance. The applicable temperature range of BOPET film is from 70℃-150℃, which can maintain excellent physical properties in a wide temperature range and is suitable for most of the product packaging.

Excellent barrier performance. It has excellent comprehensive water and air barrier performance, unlike nylon which is greatly affected by humidity, its water resistance is similar to PE, and its air permeability coefficient is extremely small. It has very high barrier property to air and odor, and is one of the materials for keeping fragrance.

Chemical resistance, resistant to oils and greases, most solvents and dilute acids and alkalis.

(2)BOPA FILM

BOPA films have excellent toughness. Tensile strength, tear strength, impact strength and rupture strength are among the best in plastic materials.

Outstanding flexibility, pinhole resistance, not easy for the contents of the puncture, is a major feature of BOPA, good flexibility, but also make the packaging feel good.

Good barrier properties, good fragrance retention, resistance to chemicals other than strong acids, especially excellent oil resistance.

With a wide range of operating temperatures and a melting point of 225°C, it can be used for long periods of time between -60°C and 130°C. The mechanical properties of BOPA are maintained at both low and high temperatures.

The performance of BOPA film is greatly affected by humidity, and both dimensional stability and barrier properties are affected by humidity.After BOPA film is subjected to moisture, in addition to wrinkling, it will generally elongate horizontally. Longitudinal shortening, elongation rate of up to 1%.

(3) CPP film polypropylene film, high temperature resistance, good heat sealing performance;

CPP film that is cast polypropylene film, CPP general cooking film using binary random copolypropylene raw materials, the film bag made of 121-125 ℃ high-temperature sterilization can withstand 30-60 minutes.

CPP high-temperature cooking film using block copolypropylene raw materials, made of film bags can withstand 135 ℃ high temperature sterilization, 30 minutes.

Performance requirements are: Vicat softening point temperature should be greater than the cooking temperature, impact resistance should be good, good media resistance, fish-eye and crystal point should be as little as possible.

Can withstand 121 ℃ 0.15Mpa pressure cooking sterilization, almost maintain the shape of the food, flavor, and the film will not crack, peel, or adhesion, has good stability; often with nylon film or polyester film composite, packaging containing soup type of food, as well as meatballs, dumplings, rice, and other processed frozen food.

(4) Aluminum Foil

Aluminum foil is the only metal foil in the flexible packaging materials, aluminum foil is a metal material, its water-blocking, gas-blocking, light blocking, flavor retention is any other package material is difficult to compare. Aluminum foil is the only metal foil in flexible packaging materials. Can withstand 121 ℃ 0.15Mpa pressure cooking sterilization, to ensure the shape of the food, flavor, and the film will not crack, peel, or adhesion, has good stability; often with nylon film or polyester film composite, packaging containing soup food, and meatballs, dumplings, rice and other processed frozen food.

(5)INK

Steamer bags using polyurethane-based ink for printing, the requirements of low residual solvents, high composite strength, no discoloration after cooking, no delamination, wrinkles, such as cooking temperature exceeds 121 ℃, a certain percentage of hardener should be added to increase the temperature resistance of the ink.

Ink hygiene is extremely important, heavy metals such as cadmium, lead, mercury, chromium, arsenic and other heavy metals can pose a serious danger to the natural environment and the human body. Secondly, the ink itself is the composition of the material, ink a variety of links, pigments, dyes, a variety of additives, such as defoaming, antistatic, plasticizers and other security risks. Should not be allowed to add a variety of heavy metal pigments, glycol ether and ester compounds. Solvents may contain benzene, formaldehyde, methanol, phenol, linkers may contain free toluene diisocyanate, pigments may contain PCBs, aromatic amines and so on.

(6) Adhesives

Steamer Retorting bag composite using two-component polyurethane adhesive, the main agent has three kinds: polyester polyol, polyether polyol, polyurethane polyol. There are two types of curing agents: aromatic polyisocyanate and aliphatic polyisocyanate. The better high temperature resistant steaming adhesive has the following characteristics:

●High solids, low viscosity, good spreadability.

●Great initial adhesion, no loss of peel strength after steaming, no tunneling in production, no wrinkling after steaming.

●The adhesive is hygienically safe, non-toxic and odorless.

●Faster reaction speed and shorter maturation time (within 48 hours for plastic-plastic composite products and 72 hours for aluminum-plastic composite products).

●Low coating volume, high bonding strength, high heat sealing strength, good temperature resistance.

●Low dilution viscosity, can be high solid state work, and good spreadability.

●Wide range of application, suitable for a variety of films.

●Good resistance to resistance (heat, frost, acid, alkali, salt, oil, spicy, etc.).

The hygiene of adhesives begins with the production of the primary aromatic amine PAA (primary aromatic amine), which originates from the chemical reaction between aromatic isocyanates and water in printing two-component inks and laminating adhesives.The formation of PAA is derived from aromatic isocyanates, but not from aliphatic isocyanates, acrylics, or epoxy-based adhesives.The presence of unfinished, low-molecular substances and residual solvents can also pose a safety hazard. The presence of unfinished low molecules and residual solvents can also pose a safety hazard.

3.The main structure of the cooking bag

According to the economic and physical and chemical properties of the material, the following structures are commonly used for cooking bags.

TWO layers:PET/CPP,BOPA/CPP,GL-PET/CPP.

THREE Layers:PET/AL/CPP, BOPA/AL/CPP, PET/BOPA/CPP,

GL-PET/BOPA/CPP,PET/PVDC/CPP,PET/EVOH/CPP,BOPA/EVOH/CPP

FOUR LAYERS:PET/PA/AL/CPP, PET/AL/PA/CPP

Multi-storey structure.

PET/ EVOH coextruded film /CPP, PET/PVDC coextruded film /CPP,PA/PVDC coextruded film /CPP PET/EVOH coextruded film, PA/PVDC coextruded film

4. Analysis of the structural characteristics of the cooking bag

The basic structure of the cooking bag consists of surface layer/intermediate layer/heat sealing layer. The surface layer is generally made of PET and BOPA, which plays the role of strength support, heat resistance and good printing. The intermediate layer is made of Al, PVDC, EVOH, BOPA, which mainly plays the role of barrier, light shielding, double-sided composite, etc. The heat sealing layer is made of various types of CPP, EVOH, BOPA, and so on. Heat sealing layer selection of various types of CPP, co-extruded PP and PVDC, EVOH co-extruded film, 110 ℃ below the cooking also have to choose LLDPE film, mainly to play a role in heat sealing, puncture resistance, chemical resistance, but also low adsorption of the material, hygiene is good.

4.1 PET/glue/PE

This structure can be changed to PA / glue / PE, PE can be changed to HDPE, LLDPE, MPE, in addition to a small number of special HDPE film, due to the temperature resistance by the PE, generally used for 100 ~ 110 ℃ or so sterilized bags; glue can be selected from ordinary polyurethane glue and boiling glue, not suitable for meat packaging, barrier is poor, the bag will be wrinkled after steaming, and sometimes the inner layer of the film stick to each other. Essentially, this structure is just a boiled bag or pasteurized bag.

4.2 PET/glue/CPP

This structure is a typical transparent cooking bag structure, can be packaged most of the cooking products, which is characterized by the visibility of the product, you can directly see the contents, but can not be packaged need to avoid the light of the product. The product is hard to the touch, often need to punch rounded corners. This structure of the product is generally 121 ℃ sterilization, ordinary high-temperature cooking glue, ordinary grade cooking CPP can be. However, the glue should choose a small shrinkage rate of the grade, otherwise the contraction of the glue layer to drive the ink to move, there is a possibility of delamination after steaming.

4.3 BOPA/glue/CPP

This is a common transparent cooking bags for 121 ℃ cooking sterilization, good transparency, soft touch, good puncture resistance. The product also can not be used for the need to avoid light product packaging.

Due to the BOPA moisture permeability is large, there are printed products in the steaming easy to produce color permeability phenomenon, especially the red series of ink penetration to the surface, the production of ink often need to add a curing agent to prevent. In addition, due to the ink in the BOPA when the adhesion is low, but also easy to produce anti-stick phenomenon, especially in high humidity environment. Semi-finished products and finished bags in processing must be sealed and packaged.

4.4 KPET/CPP、KBOPA/CPP

This structure is not commonly used, the product transparency is good, with high barrier properties, but can only be used for sterilization below 115 ℃, temperature resistance is slightly worse, and there are doubts about its health and safety.

4.5 PET/BOPA/CPP

This structure of the product is high strength, good transparency, good puncture resistance, due to PET, BOPA shrinkage rate difference is large, generally used for 121 ℃ and below the product packaging.

The contents of the package is more acidic or alkaline when the choice of this structure of products, rather than using aluminum-containing structure.

The outer layer of glue can be used to select the boiled glue, the cost can be appropriately reduced.

4.6 PET/Al/CPP

This is the most typical non-transparent cooking bag structure, according to the different inks, glue, CPP, cooking temperature from 121 ~ 135 ℃ can be used in this structure.

PET/one-component ink/high-temperature adhesive/Al7µm/high-temperature adhesive/CPP60µm structure can reach 121℃ cooking requirements.

PET/Two-component ink/High-temperature adhesive/Al9µm/High-temperature adhesive/High-temperature CPP70µm structure can be higher than 121℃ cooking temperature, and the barrier property is increased, and the shelf-life is extended, which can be more than one year.

4.7 BOPA/Al/CPP

This structure is similar to the above 4.6 structure, but due to the large water absorption and shrinkage of BOPA, it is not suitable for high-temperature cooking above 121 ℃, but the puncture resistance is better, and it can meet the requirements of 121 ℃ cooking.

4.8 PET/PVDC/CPP、BOPA/PVDC/CPP

This structure of the product barrier is very good, suitable for 121 ℃ and the following temperature cooking sterilization, and oxygen has a high barrier requirements of the product.

The PVDC in the above structure can be replaced by EVOH, which also has high barrier property, but its barrier property decreases obviously when it is sterilized at high temperature, and BOPA can not be used as the surface layer, otherwise the barrier property decreases sharply with the increase of temperature.

4.9 PET/Al/BOPA/CPP

This is a high-performance construction of cooking pouches that can package virtually any cooking product and can also withstand cooking temperature at 121 to 135 degrees Celsius.

Structure I: PET12µm/high-temperature adhesive/Al7µm/high-temperature adhesive/BOPA15µm/high-temperature adhesive/CPP60µm, this structure has good barrier, good puncture resistance, good light-absorbing strength, and it is a kind of excellent 121℃ cooking bag.

Structure II: PET12µm/high-temperature adhesive/Al9µm/high-temperature adhesive/BOPA15µm/high-temperature adhesive/high-temperature CPP70µm, this structure, in addition to all the performance characteristics of structure I, has the characteristics of 121 ℃ and above the high-temperature cooking. Structure III: PET/glue A/Al/glue B/BOPA/glue C/CPP, the amount of glue of glue A is 4g/㎡, the amount of glue of glue B is 3g/㎡, and the amount of glue of glue C is 5-6g/㎡, which can satisfy the requirements, and reduce the amount of glue of glue A and glue B, which can save the cost appropriately.

In the other case, glue A and glue B are made of better boiling grade glue, and glue C is made of high temperature resistant glue, which can also meet the requirement of 121℃ boiling, and at the same time reduce the cost.

Structure IV: PET/glue/BOPA/glue/Al/glue/CPP, this structure is BOPA switched position, the overall performance of the product has not changed significantly, but the BOPA toughness, puncture resistance, high composite strength and other advantageous features, did not give full play to this structure, therefore, the application of relatively few.

4.10 PET/ Co-extruded CPP

Co-extruded CPP in this structure generally refers to 5-layer and 7-layer CPP with high barrier properties, such as:

PP/bonding layer/EVOH/bonding layer/PP;

PP/bonding layer/PA/bonding layer/PP;

PP/bonded layer/PA/EVOH/PA/bonded layer/PP, etc;

Therefore, the application of co-extruded CPP increases the toughness of the product, reduces the breakage of packages during vacuuming, high pressure, and pressure fluctuations, and extends the retention period due to the improved barrier properties.

In short, the structure of the high-temperature cooking bag variety, the above is only a preliminary analysis of some common structure, with the development of new materials, new technologies, there will be more newer structures, so that the cooking packaging has a greater choice.

Post time: Jul-13-2024