Laminated packaging is widely used in various industries for its strength, durability, and barrier properties. The commonly used plastic materials for laminated packaging include:

| Materilas | Thickness | Density(g / cm3) | WVTR (g / ㎡.24hrs) |

O2 TR (cc / ㎡.24hrs) |

Application | Properties |

| NYLON | 15µ,25µ | 1.16 | 260 | 95 | Sauces, spices, powdered products, jelly products and liquid products. | Low temperature resistance, high temperature end-use, good seal-ability and good vacuum retention. |

| KNY | 17µ | 1.15 | 15 | ≤10 | Frozen processed meat, Product with high moisture content, Sauces, condiments and Liquid soup mix. | Good moisture barrier, High oxygen and aroma barrier, Low temperature and Good vacuum retention. |

| PET | 12µ | 1.4 | 55 | 85 | Versatile for different food products, products derived from rice, snacks, fried products, tea &coffee and soup condiment. | High moisture barrier and moderate oxygen barrier |

| KPET | 14µ | 1.68 | 7.55 | 7.81 | Mooncake, Cakes, Snacks, Process product, Tea and Pastas. | High moisture barrier, Good oxygen and Aroma barrier and Good oil resistance. |

| VMPET | 12µ | 1.4 | 1.2 | 0.95 | Versatile for different food products, rice derived products, snacks, deep fried products, tea and soup mixes. | Excellent moisture barrier, good low temperature resistance, excellent light barrier and excellent aroma barrier. |

| OPP - Oriented Polypropylene | 20µ | 0.91 | 8 | 2000 | Dry products, biscuits, popsicles and chocolates. | Good moisture barrier, good low temperature resistance, good light barrier and good stiffness. |

| CPP - Cast Polypropylene | 20-100µ | 0.91 | 10 | 38 | Dry products, biscuits, popsicles and chocolates. | Good moisture barrier, good low temperature resistance, good light barrier and good stiffness. |

| VMCPP | 25µ | 0.91 | 8 | 120 | Versatile for different food products, rice derived products, snacks, deep fried products, tea and soup seasoning. | Excellent moisture barrier, high oxygen barrier, good light barrier and good oil barrier. |

| LLDPE | 20-200µ | 0.91-0.93 | 17 | / | Tea, confectioneries, cakes, nuts, pet food and flour. | Good moisture barrier、oil resistance and aroma barrier. |

| KOP | 23µ | 0.975 | 7 | 15 | Food Packaging such as snacks, grains, beans, and pet food. Their moisture resistance and barrier properties help keep products fresh.cements, powders, and granules | High moisture barrier, good oxygen barrier, good aroma barrier and good oil resistance. |

| EVOH | 12µ | 1.13~1.21 | 100 | 0.6 | Food Packaging,Vacuum Packaging,Pharmaceuticals,Beverage Packaging,Cosmetics and Personal Care Products,Industrial Products,Multi-Layer Films | High transparency. Good print oil resistance and moderate oxygen barrier. |

| ALUMINIUM | 7µ 12µ | 2.7 | 0 | 0 | Aluminum pouches are commonly used to package snacks, dried fruits, coffee, and pet foods. They protect contents from moisture, light, and oxygen, extending shelf life. | Excellent moisture barrier, excellent light barrier and excellent aroma barrier. |

These various plastic materials are often chosen based on the specific requirements of the product being packaged, such as moisture sensitivity, barrier needs, shelf life, and environmental considerations.Usually used to shaped as 3 side sealed bags, 3 side sealed zipper bags,Laminated Packaging Film for Automatic Machines,Stand-up Zipper Pouches,Microwaveable Packaging Film/Bags,Fin Seal Bags,Retort Sterilization Bags.

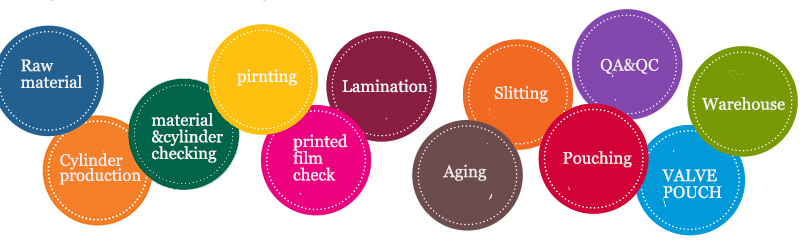

Flexible lamination pouches process:

Post time: Aug-26-2024