Packaging can be classified according to its role in the circulation process, packaging structure, material type, packaged product, sales object and packaging technology.

(1) According to the function of packaging in the circulation process, it can be divided into sales packaging and transportation packaging . Sales packaging, also known as small packaging or commercial packaging, not only serves to protect the product, but also pays more attention to the promotion and value-added functions of the product packaging. It can be integrated into the packaging design method to establish the product and corporate image and attract consumers. Improve product competitiveness. Bottles, cans, boxes, bags and their combined packaging generally belong to sales packaging. Transport packaging, also known as bulk packaging, is generally required to have better protection functions. It is convenient for storage and transportation. On the outer surface of the loading and unloading function, there are text descriptions or diagrams of product instructions, storage and transportation precautions. Corrugated boxes, wooden boxes, metal vats, pallets, and containers are transport packages.

(2) According to the packaging structure, packaging can be divided into skin packaging, blister packaging, heat shrinkable packaging, portable packaging, tray packaging and combined packaging.

(3) According to the type of packaging materials, it includes packaging made of paper and cardboard, plastic, metal, composite materials, glass ceramics, wood and other materials.

(4) According to the packaged products, the packaging can be divided into food packaging, chemical product packaging, toxic substance packaging, broken food packaging, flammable product packaging, handicraft packaging, home appliance product packaging, miscellaneous product packaging, etc.

(5) According to the sales object, the packaging can be divided into export packaging, domestic sales packaging, military packaging and civilian packaging, etc.

(6) According to packaging technology, packaging can be divided into vacuum inflation packaging, controlled atmosphere packaging, deoxygenation packaging, moisture-proof packaging, soft can packaging, aseptic packaging, thermoforming packaging, heat shrinkable packaging, cushioning packaging, etc.

The same is true for the classification of food packaging, as follows: according to different packaging materials, food packaging can be divided into metal, glass, paper, plastic, composite materials, etc.; according to different packaging forms, food packaging can be divided into cans, bottles, bags, etc. , bags, rolls, boxes, boxes, etc.; according to different packaging technologies, food packaging can be divided into canned, bottled, sealed, bagged, wrapped, filled, sealed, labeled, coded, etc.; Different, food packaging can be divided into inner packaging, secondary packaging, tertiary packaging, outer packaging, etc.; according to different techniques, food packaging can be divided into: moisture-proof packaging, waterproof packaging, mildew-proof packaging, fresh-keeping packaging, quick-frozen packaging, breathable packaging , Microwave sterilization packaging, aseptic packaging, inflatable packaging, vacuum packaging, deoxygenation packaging, blister packaging, skin packaging, stretch packaging, retort packaging, etc.

The various packages mentioned above are all made of different composite materials, and their packaging characteristics correspond to the requirements of different foods and can effectively protect the quality of food.

Different foods should choose food packaging bags with different material structures according to the characteristics of the food. So what kind of food is suitable for what material structure as food packaging bags? Let me explain to you today. Customers who need customized food packaging bags can refer to one time.

1. Retort packaging bag

Product requirements: Used for packaging of meat, poultry, etc., the packaging is required to have good barrier properties, resistance to bone holes, and no breakage, no cracking, no shrinkage, and no peculiar smell under sterilization conditions. Design Structure: Transparent: BOPA/CPP, PET/CPP, PET/BOPA/CPP, BOPA/PVDC/CPP, PET/PVDC/CPP, GL-PET/BOPA/CPP Aluminum Foil: PET/AL/CPP, PA/ AL/CPP, PET/PA/AL/CPP, PET/AL/PA/CPP Reason: PET: high temperature resistance, good rigidity, good printability, high strength. PA: High temperature resistance, high strength, flexibility, good barrier properties, and puncture resistance. AL: Best barrier properties, high temperature resistance. CPP: High temperature resistant cooking grade, good heat sealing performance, non-toxic and tasteless. PVDC: high temperature resistant barrier material. GL-PET: Ceramic vapor-deposited film with good barrier properties and microwave transmission. For specific products to choose the appropriate structure, transparent bags are mostly used for cooking, and AL foil bags can be used for ultra-high temperature cooking.

2. Puffed snack food packaging bags

Product requirements: Oxygen resistance, water resistance, light protection, oil resistance, fragrance retention, scratchy appearance, bright colors, and low cost. Design structure: BOPP/VMCPP Reason: Both BOPP and VMCPP are scratchable, and BOPP has good printability and high gloss. VMCPP has good barrier properties, keeps fragrance and moisture. CPP oil resistance is also better

3.biscuit packaging bag

Product requirements: good barrier properties, strong shading properties, oil resistance, high strength, odorless and tasteless, and the packaging is quite scratchy. Design structure: BOPP/EXPE/VMPET/EXPE/S-CPP Reason: BOPP has good rigidity, good printability and low cost. VMPET has good barrier properties, avoid light, oxygen and water. S-CPP has good low temperature heat sealability and oil resistance.

4.milk powder packaging bag

Product requirements: long shelf life, fragrance and taste preservation, anti-oxidative deterioration, anti-moisture absorption and agglomeration. Design structure: BOPP/VMPET/S-PE Reason: BOPP has good printability, good gloss, good strength, and moderate price. VMPET has good barrier properties, light protection, good toughness, and metallic luster. It is better to use enhanced PET aluminum plating, and the AL layer is thick. S-PE has good anti-pollution sealing performance and low temperature heat sealing performance.

5. Green tea packaging

Product requirements: anti-deterioration, anti-discoloration, anti-taste, that is, to prevent the oxidation of protein, chlorophyll, catechin, and vitamin C contained in green tea. Design structure: BOPP/AL/PE, BOPP/VMPET/PE, KPET/PE Reason: AL foil, VMPET, and KPET are all materials with excellent barrier properties, and have good barrier properties to oxygen, water vapor, and odor. AK foil and VMPET are also excellent in light protection. Moderately priced product

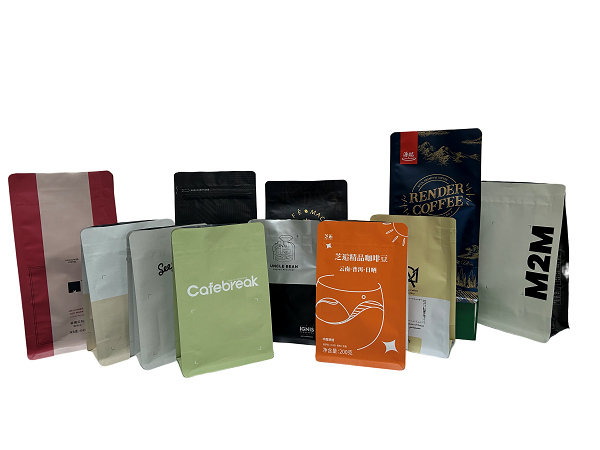

6. Packaging for coffee beans and coffee powder

Product requirements: anti-water absorption, anti-oxidation, resistance to hard lumps of the product after vacuuming, and keeping the volatile and easily oxidized aroma of coffee. Design structure: PET/PE/AL/PE, PA/VMPET/PE Reason: AL, PA, VMPET have good barrier properties, water and gas barrier, and PE has good heat sealability.

7.Chocolate and chocolate product packaging

Product requirements: good barrier properties, light-proof, beautiful printing, low-temperature heat sealing. Design Structure: Pure Chocolate Varnish/Ink/White BOPP/PVDC/Cold Seal Gel Brownie Varnish/Ink/VMPET/AD/BOPP/PVDC/Cold Seal Gel Reason: PVDC and VMPET are high barrier materials, cold seal The glue can be sealed at an extremely low temperature, and the heat will not affect the chocolate. Since the nuts contain more oil, which is easy to oxidize and deteriorate, an oxygen barrier layer is added to the structure.

Post time: May-26-2023