High temperature steaming bags and boiling bags are both made of composite materials,all belong to composite packaging bags. Common materials for boiling bags include NY/CPE, NY/CPP, PET/CPE, PET/CPP, PET/PET/CPP, and so on. The materials commonly used for steaming and cooking packaging include NY/CPP, PET/CPP, NY/NY/CPP, PET/PET/CPP, PET/AL/CPP, PET/AL/NY/CPP, etc.

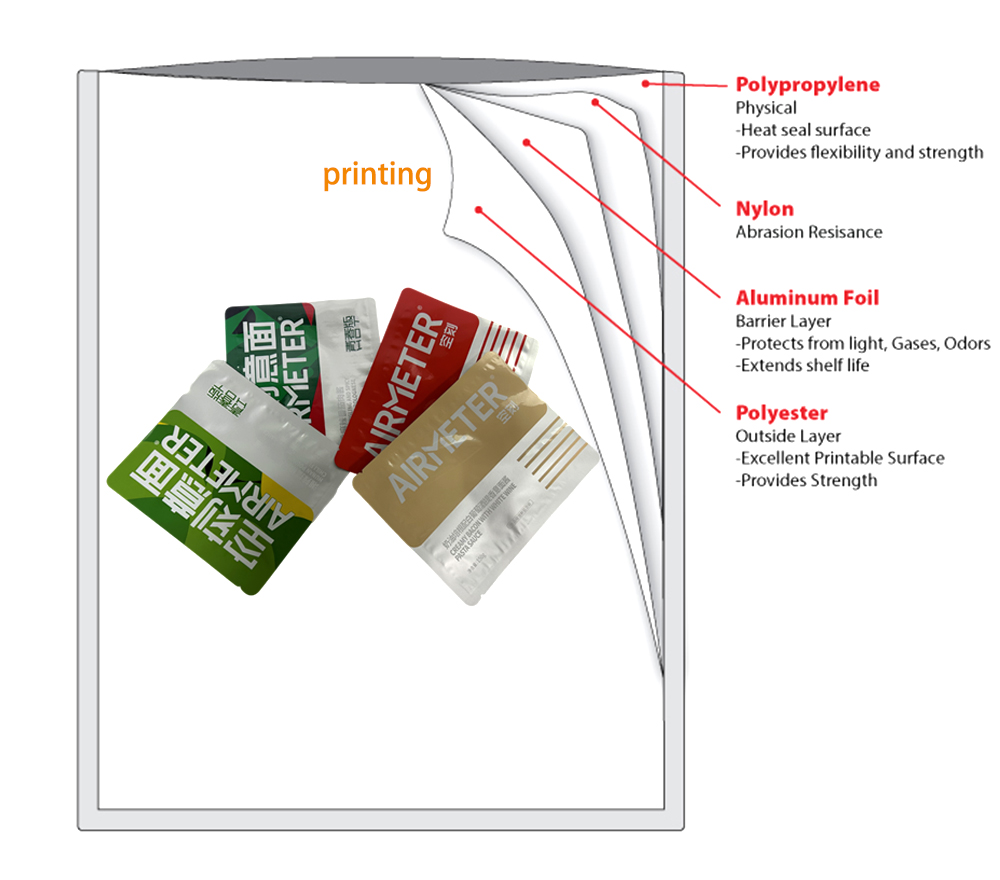

Representative steaming and cooking bag structures have an outer layer of polyester film for reinforcement; The middle layer is made of aluminum foil, which is used for light, moisture, and gas leakage prevention; The inner layer is made of polyolefin film (such as polypropylene film), used for heat sealing and contact with food.

Steaming bags are used for packaging food products, so the safety and sterility requirements for plastic bags are generally high in the production process, and they cannot be contaminated by various bacteria. However, it is inevitable in the actual production process, so the sterilization of steaming bags is particularly important. The sterilization of steaming bags can be mainly divided into three categories,

There are three sterilization methods for cooking bags, namely general sterilization, high-temperature sterilization, and high-temperature resistant sterilization.

General sterilization, steaming temperature between 100-200 ℃, sterilization for 30 minutes;

The first type: high temperature type, steaming temperature at 121 degrees Celsius, sterilization for 45 minutes;

The second type:high temperature resistant, with a cooking temperature of 135 degrees Celsius and a sterilization time of fifteen minutes. Suitable for sausage, traditional Chinese rice-pudding and other food. The third type: Steaming bags have the characteristics of moisture resistance, light shielding, temperature resistance, and fragrance preservation, and are suitable for use in cooked foods such as meat, ham, etc.

Water boiling bags are another type of plastic bag belonging to vacuum bags, mainly made of PA+PET+PE, or PET+PA+AL materials. The characteristic of water boiling bags is that they undergo anti-virus treatment at a temperature not exceeding 110 ℃, with good oil resistance, high heat sealing strength, and strong impact resistance.

Water boiled bags are usually sterilized with water, and there are two ways to sterilize them,

The first method is low-temperature sterilization, which lasts for half an hour at a temperature of 100 ℃

Second method: Bus sterilization, continuously sterilizing for half an hour at a temperature of 85 ℃

Simply put, the sterilization method of boiled water bags is to utilize the heat resistance of bacteria and treat them with appropriate temperature or insulation time to completely kill them.

From the above sterilization methods, it can be seen that there is still a significant difference between boiling bags and steaming bags. The most obvious difference is that the sterilization temperature of steaming bags is generally higher than that of boiling bags.

Post time: Nov-14-2024