Common food packages are divided into two categories, frozen food packages and room temperature food packages. They have completely different material requirements for packaging bags. It can be said that the packaging bags for room temperature cooking bags are more complicated, and the requirements are stricter.

1. Requirements for materials for cooking package sterilization in production:

Whether it is a frozen food package or a room temperature food package, a key production process is the sterilization of the food package, which is divided into pasteurization, high-temperature sterilization, and ultra-high temperature sterilization. It is necessary to choose the corresponding temperature that can withstand this sterilization. Packaging bag material, there are different options of 85°C-100°C-121°C-135°C on the packaging bag material, if it does not match, the packaging bag will wrinkle, delaminate, melt, etc.

2. Requirements for materials, soup, oil and fat:

Most of the ingredients in the cooking bag will have soup and fat. After the bag is heat-sealed and heated continuously at high temperature, the bag will expand. The material requirements must consider ductility, toughness, and barrier properties.

3. Storage conditions Requirements for materials:

1). Frozen cooking packages need to be stored at minus 18°C and transported through the cold chain. The requirement for this material is that it has better freeze resistance.

2). Normal temperature cooking bags have higher requirements on materials. The problems to be faced in normal temperature storage will involve ultraviolet radiation, bumping and extrusion during transportation, and the materials have extremely high requirements on light resistance and toughness.

4. Material requirements for consumer heating packaging bags:

The heating of the cooking package before eating is nothing more than boiling, microwave heating and steaming. When heating together with the packaging bag, you need to pay attention to the following two points:

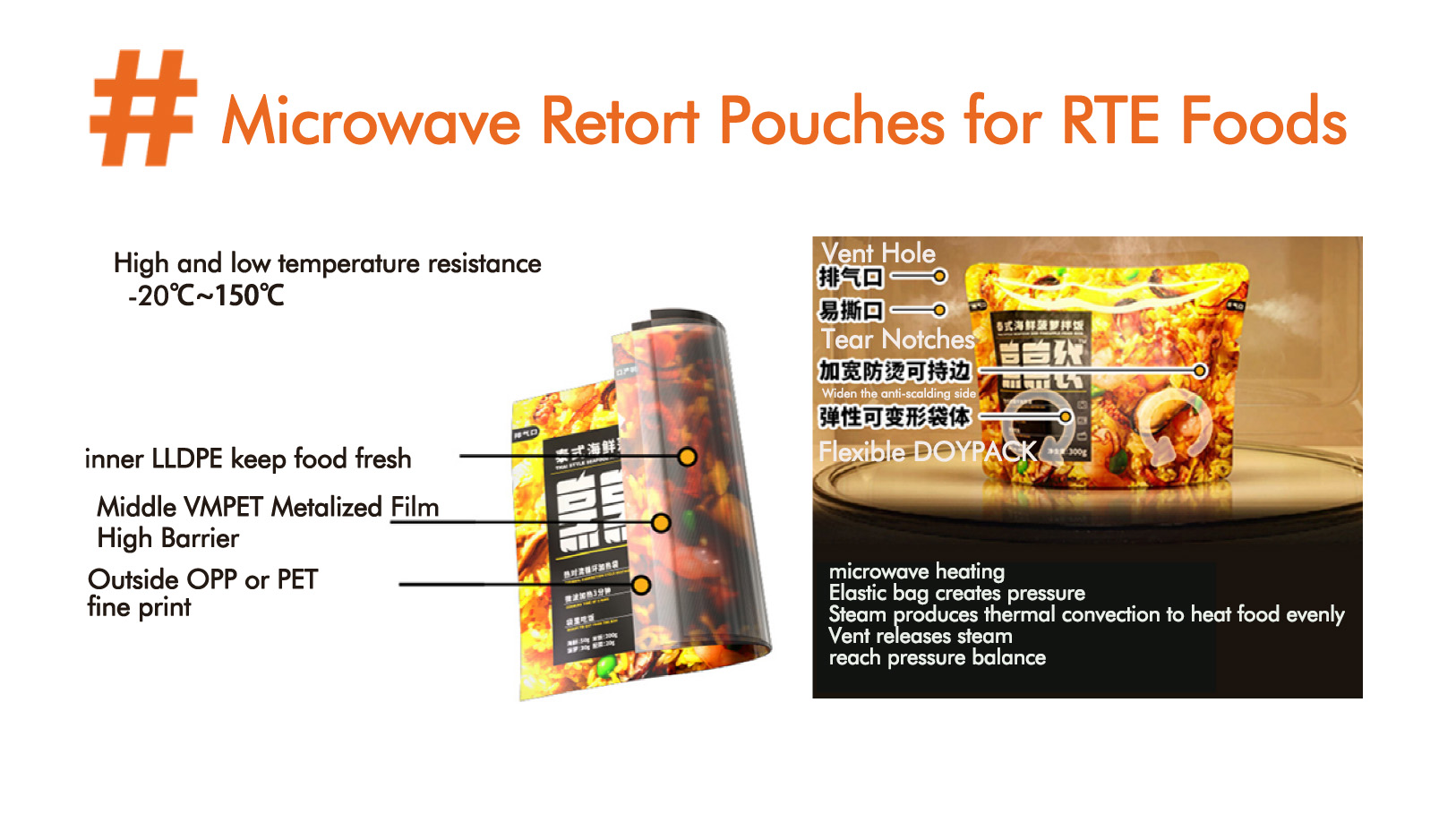

1). Packaging bags containing aluminum-plated or pure aluminum materials are prohibited to be heated in a microwave oven. The common sense of microwave ovens tells us that there is a danger of explosion when metal is placed in a microwave oven.

2). It is best to control the heating temperature below 106°C. The bottom of the boiling water container will exceed this temperature. It is best to put something on it. This point is considered for the inner material of the packaging bag, which is boiled PE. , It doesn’t matter if it is RCPP that can withstand high temperature above 121°C.

The direction of packaging innovation for prepared dishes will focus on the development of transparent high-barrier packaging, emphasizing experience, increasing interaction, improving packaging automation, expanding consumption scenarios, and sustainable packaging:

1, packaging makes the processing of prepared dishes more convenient. For example, Simple Steps, an easy-to-meal bag technology launched by Sealed Air Packaging, allows processing plants to simplify the processing steps. At the same time, consumers can cook in microwaves. No knives or scissors are needed when unpacking. There is no need to replace the container when using it, and it can be automatically exhausted.

2: Packaging optimizes consumer experience. The straight-line easy-to-open flexible packaging solution launched by Pack Mic.Co.,Ltd. The straight-line easy-to-tear will not damage the structure of the packaging material. Even at -18°C, it still has excellent direct tear ability after 24 hours of freezing. With microwave packaging bags, consumers can hold both sides of the bag and take it out of the microwave to heat pre-made dishes directly to avoid burning their hands.

3, packaging makes the quality of prepared dishes more delicious. Pack Mic’s high-barrier plastic container can better protect the content from the loss of fragrance and prevent the penetration of external oxygen molecules and can also be heated by microwave.

Post time: Sep-05-2023