Choosing flexible plastic pouches and films over traditional containers like bottles, jars, and bins offers several advantages:

Weight and Portability: Flexible pouches are significantly lighter than rigid containers, making them easier to transport and handle.

Space Efficiency: Pouches can be flattened when empty, saving space in storage and during transportation. This can lead to lower shipping costs and more efficient use of shelf space.

Material Usage: Flexible packaging typically uses less material than rigid containers, which can reduce environmental impact and production costs.

Sealing and Freshness: Pouches can be sealed tightly, providing better protection against moisture, air, and contaminants, which helps maintain product freshness.

Customization: Flexible packaging can be easily customized in terms of size, shape, and design, allowing for more creative branding and marketing opportunities.

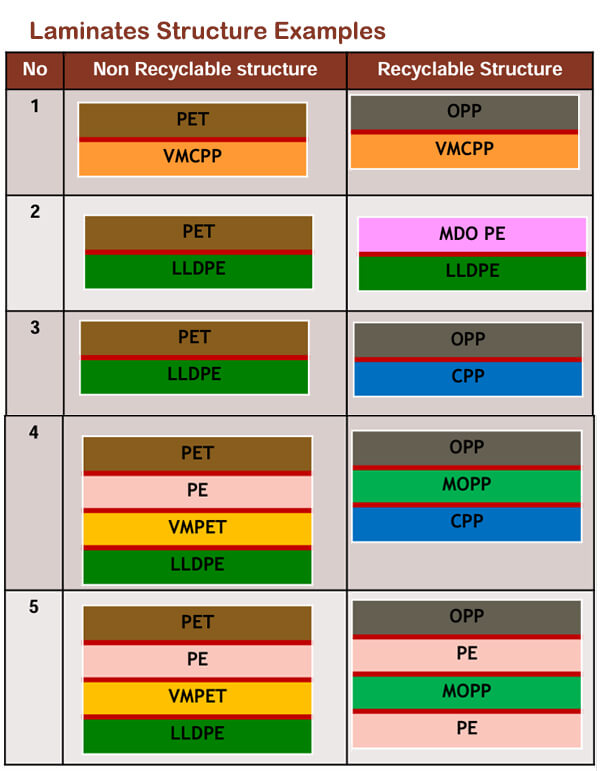

Common material structures options:

Rice / pasta packaging :PE/PE, Paper/CPP, OPP/CPP,OPP/PE,OPP

Frozen Food packaging:PET/AL/PE,PET/PE,MPET/PE,OPP/MPET/PE

Snacks/Chips packaging:OPP/CPP,OPP/OPP Barrier,OPP/MPET/PE

Biscuits&chocolate packaging:OPP Treated,OPP/MOPP, PET/MOPP,

Salami and Cheese packaging: Lids film PVDC/PET/PE

Bottom film (tray)PET/PA

Bottom film(tray)LLDPE/EVOH/LLDPE+PA

Soups/sauces/Spices packaging:PET/EVOH,PET/AL/PE,PA/PE,PET/PA/RCPP,PET/AL/PA/RCPP

Cost-Effectiveness: The production and material costs for flexible pouches are often lower than those for rigid containers, making them a more economical choice for manufacturers.

Recyclability: Many flexible plastic films and pouches are recyclable, and advancements in materials are making them more sustainable.

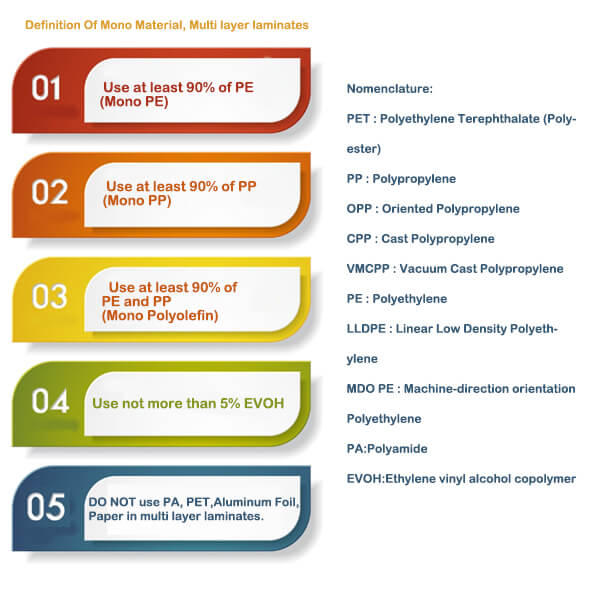

Recyclability of plastic packaging refers to the ability of the plastic material to be collected, processed, and reused in the production of new products. A globally accepted definition encompasses several key aspects:The packaging must be designed in a way that facilitates its collection and sorting in recycling facilities. This includes considerations for labeling and the use of single materials rather than composites.The plastic must be able to undergo mechanical or chemical recycling processes without significant degradation in quality, allowing it to be transformed into new products.There must be a viable market for the recycled material, ensuring that it can be sold and used in manufacturing new products.

-Mono-material packaging is easier to recycle compared to multi-material packaging. Since it consists of only one type of plastic, it can be processed more efficiently in recycling facilities, leading to higher recycling rates.

-With only one type of material, there is less risk of contamination during the recycling process. This improves the quality of the recycled material and makes it more valuable.

-Mono-material packaging is often lighter than multi-material alternatives, which can reduce transportation costs and lower carbon emissions during shipping.

-Certain mono-materials can provide excellent barrier properties, helping to extend the shelf life of products while maintaining their quality.

This definition aims to promote a circular economy, where plastic packaging is not merely discarded but reintegrated into the production cycle.

Consumer Convenience: Pouches often come with features like resealable zippers or spouts, enhancing user convenience and reducing waste.

Flexible plastic pouches and films provide a versatile, efficient, and often more sustainable packaging solution compared to traditional rigid containers.

Post time: Sep-02-2024