PACK MIC has a 10,000-square-meter factory featuring a 300,000 level purification workshop and multiple production lines for an integrated process from raw material

inspection to printing, lamination, and slitting. Attentive to both "technological innovation" and "sustainable development," the company pushes packaging products to

"lightweight, recyclable, and low-carbon eco-friendly" levels with the introduction of advanced equipment and building specialized talent. Meanwhile, it follows a digital operation management system to implement efficient and flexible production, which

makes it possible for customers to enhance market competitiveness. There is a team of

professionals offering customized solutions. We constantly innovate in packaging

materials (functionality, barrier performance), structural design (user experience, freshness maintenance), and printing methods(beauty quality, anti-counterfeiting, environmental inks) to create technical barriers. Our extremely flexible customization capabilities can react rapidly to different, customized requirements to deliver maximum customer satisfaction.

We have a full control qualty control system which comply with BRC and FDA and ISO 9001 standard in per manufacturing process. Packaging is the most important factor in protecting goods from damage. QA/QC helps ensure that your packaging is up to standard and that your products are appropriately protected. Quality control (QC) is product-oriented and focuses on defect detection, while quality assurance (QA) is process-oriented and focuses on defect prevention.

Common QA/QC issues that challenge manufacturers can include:

- Customer Demands

- Rising Costs of Raw Materials

- Shelf Life

- Convenience Feature

- High-Quality Graphics

- New Shapes & Sizes

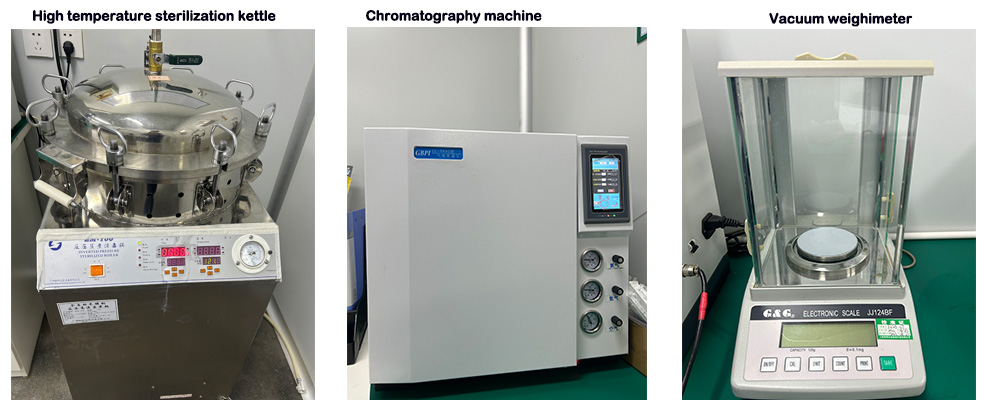

Here at Pack Mic with our high precision packaigng testing instruments coupled with our professional QA and QC experts , provide you high quality packaging pouches and rolls.We have the up-to-date QA/QC tools to ensure your package system project. In each process we test the data to make sure there are no abnormal conditions. For finished packaging rolls or pouches we do internal text before shipment. Our test including following such as

- Peel Force,

- Heat sealing strength(N/15mm) ,

- breaking force(N/15mm)

- Elongation at break (%) ,

- Tear Strength of Right-angle (N),

- Pendulum impact energy(J),

- Friction Coefficient,

- Pressure Durability,

- Drop resistance,

- WVTR (Water vapor(u)r transmission) ,

- OTR (Oxygen Transmission Rate)

- Residue

- Benzene solvent