Iifilimu ezahlukeneyo zihlala zisetyenziswa kubomi bemihla ngemihla. Zeziphi izixhobo ezenziwe zezi filimu? Zithini iimpawu zomsebenzi ngamnye? Oku kulandelayo yintshayelelo eneenkcukacha kwiifilimu zeplastiki ezisetyenziswa rhoqo kubomi bemihla ngemihla:

Ifilimu yeplastiki yifilimu eyenziwe nge-polyvinyl phelorde, polythylene, polypropylene, ipolystyrene kunye nezinye izinto zokubuyisa, zihlala zisetyenziswa ngokupakisha, njl.

Ifilimu yeplastiki inokwahlulwa ibe

Ifilimu yesiqhelo: Ifilimu ye-Blown, ifilimu ye-calence, ifilimu eyoluliweyo, ifilimu, njl.;

-Ummandla wefilimu wefilimu, ifilimu ye-mulch, njl.;

-Films yokupakisha (kubandakanya iifilimu ezihlanganisiweyo zephakheji ye-Farmaceutical, iifilimu ezihlanganisiweyo zokupakishwa kokutya, njl.njl).

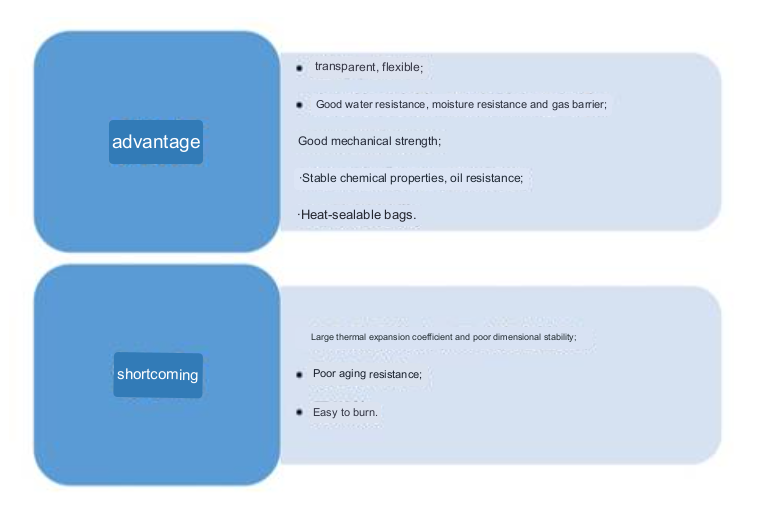

Izibonelelo kunye nokungancedi kakuhle kwifilimu yeplastiki:

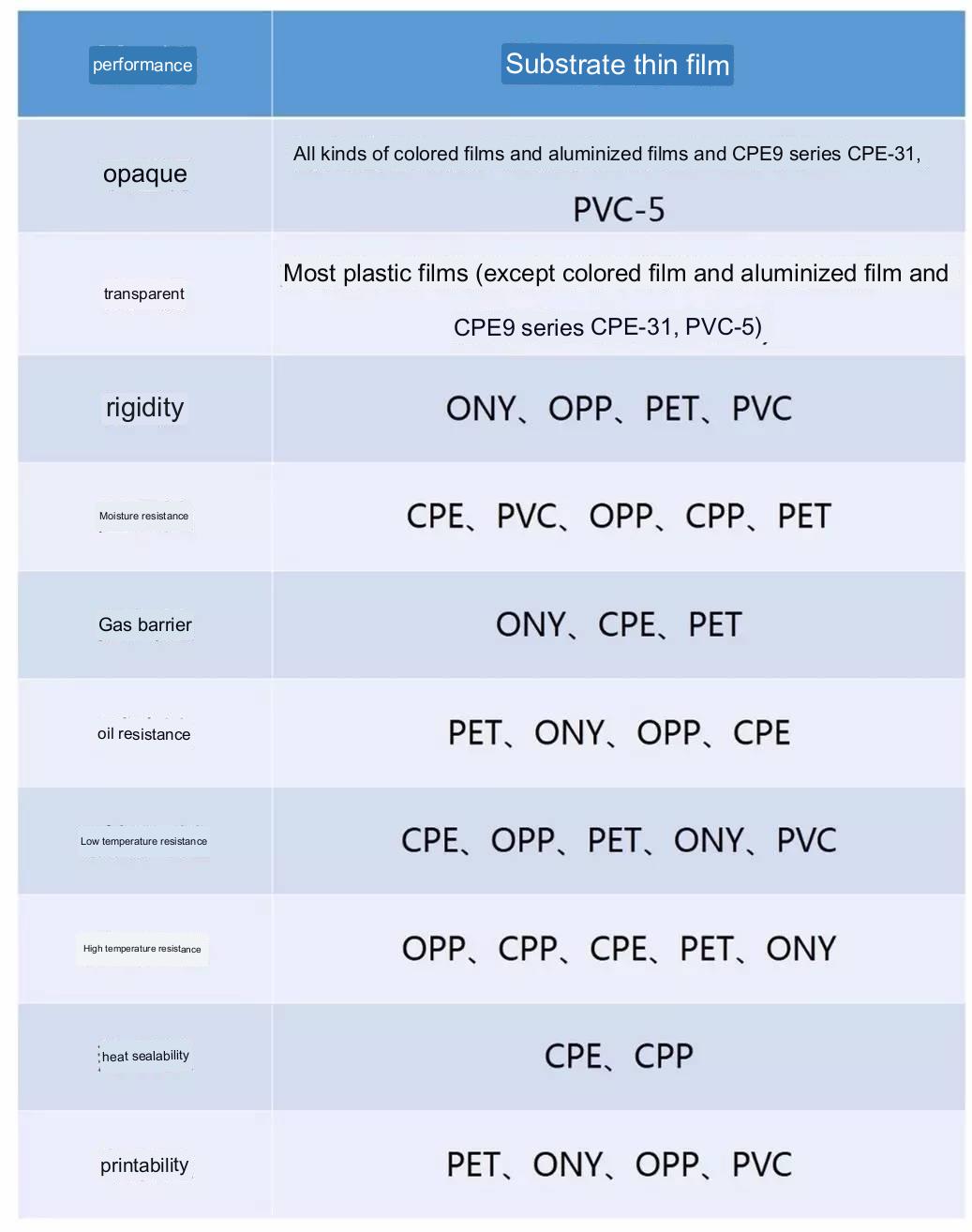

Iimpawu zentsebenzo zeefilimu zeplastiki eziphambili:

Ifilimu ye-Biaisproply Polyproplene (i-BOPP)

I-Polypropylene yi-thermoplastic relin eveliswe yi-polymerization ye-propylene. Izixhobo ze-PPly ze-PP zinobushushu obungaphantsi kobushushu obuncinci (i-100 ° C), ukungafihli kwe-100 ° sty, i-gloss ephantsi, kunye namandla aphantsi, kodwa amandla empembelelo ye-PP enyukayo ngokunyuka komxholo we-ithylene. Iqondo lokushisa le-Viccy le-PP liyi-150 ° C. Ngenxa yenqanaba eliphezulu le-crystallies, esi sixhobo sinobulungisa obungaphezulu kakhulu kunye neepropathi zokuchasana. I-PP ayinangxaki yokusebenza kwendalo.

Ifilimu ye-Biaisproply Polypropylene (i-BOPP) yezinto eziguquguqukayo eziguquguqukayo eziguqukayo zango-1960. Isebenzisa umgca okhethekileyo wemveliso ukudibanisa izinto ezingafunekiyo zePolyProplene kunye nezongezo ezisebenzayo, zinyibilike kwaye ziguqa emakhithini, emva koko zizolule kwiifilimu. Isetyenziswe ngokubanzi ekupakikweni ukutya, ipigi, icuba, iti, ijusi, ubisi, i-versing, i-kumkani ukumkanikazi ". Ukongeza, inokusetyenziselwa ukulungiswa kweemveliso ezisebenzayo ezisebenzayo ezifana ne-membrane yombane kunye neemitha ezincinci, ke amathuba ophuhliso lweefilimu ze-BOP ezibanzi kakhulu.

Ifilimu ye-BOPP ayinazo kuphela izibonelelo zokuxinana okuphezulu, ukumelana nokuziphatha okuhle kunye nokuchasana nobushushu be-PP, kodwa ikwanazo iipropathi ezifanelekileyo ze-PP, kodwa ineempawu ezintle zezinto eziphezulu kunye nemithombo etyebileyo yezixhobo ezityebileyo. Ifilimu ye-BOPE inokudityaniswa nezinye izinto ezinepropathi ekhethekileyo yokuphucula ngakumbi okanye ukuphucula ukusebenza. Izinto ezisetyenziswayo ezisetyenziswayo zibandakanya ifilimu ye-PE, i-slyproplene ye-POLLPOPLEne (CPP), i-COPPPIYLINECYNINE CHIRINIDE (PVDC), i-Aluminium yefilimu, njl.

Ifilimu ephantsi ye-Polythylene (ldP)

Ifilimu yePalylene, eyokuthiyiwe, ineempawu zokuthintela umswakama kunye nokungaphantsi komswakama.

I-Pollithylene (i-lpde) i-willing ye-willing efunyenwe yi-polymerication ralymerication ye-polymerication phantsi koxinzelelo oluphezulu, ngoko ke lubizwa ngokuba "polyebene echubekileyo". I-LPDE yimolekyuli etshatileyo enamasebe ahlukeneyo kwikhonkco eliphambili, malunga ne-15 ukuya kwi-15 ukuya kwi-Ethyl, i-Byyl okanye i-atoms okanye iiatom ezimalunga ne-atom kwi-chain yekhabhoni. Ngenxa yokuba isikhonkwane se-molecular sinemixokelelwane emide nefutshane, imveliso inoxinzelelo olusezantsi, ukumelana nobushushu obuphantsi, ukunganyangeki kweqondo lobushushu, kwaye i-Alkali, i-Alkali, i-ilkali, i-itrosion ye-ityuwa, ineempawu ezintle zombane. I-translucent kunye ne-glossy, inozinzo oluhle lwekhemikhali, ukuvutha komsindo, ukuxhathisa kwamanzi kunye nokunganyangwa kwamanzi, kwaye kunokudilizwa. Eyona nto igwenxa kakhulu ngumqobo wayo ongalunganga kwioksijini.

Ihlala isetyenziswa njengefilimu engaphakathi ye-Inner yeZinto eziguquguqukayo eziguquguqukayo, kwaye lelona filimu isetyenziswa kakhulu kwaye isebenzise ifilimu yephakethe okwangoku, inika ingxelo ngaphezulu kwe-40% yokusetyenziswa kweefilimu zephakheji zeplastiki. Zininzi iintlobo zefilimu yokupakisha i-Polythylene, kwaye imisebenzi yabo iyahlukile. Ukusebenza kwefilimu yefilimu engatshatanga ayitshatanga, kwaye ukwenziwa kwefilimu yokudibanisa kuyahambelana. Yeyona nto iphambili yokupakishwa kokutya. Okwesibini, ifilimu ye-Polythylene ikwasetyenziswa kwicandelo lobunjineli, njengejomembrane. Isebenza njengokuphumelela kwamanzi kubunjineli bobuchwephesha kwaye inomoya ophantsi kakhulu. Ifilimu yezolimo isetyenziswa kwezolimo, enokwahlulwa kwifilimu e-Shed, ifilimu ye-MLCH, ifilimu yefilimu yefilimu, ifilimu yokugcina eluhlaza kwaye njalo.

Ifilimu ye-polyester (PET)

Ifilimu ye-polyester (i-PET), ebizwa ngokuba yiPolyethylene Terefhalate yeplastikhi, yiplastiki yobunjineli bobunjineli. Sisixhobo sefilimu eyenziwe ngamaphepha aphezulu ngokuphumelela kwaye emva koko wolulelwe nge-biaisted. Ifilimu ye-polyester ibonakaliswa ziipropathi ezibalaseleyo ze-Polyester zibonakaliswa ziimpawu ezibalaseleyo ze-Polyster, ubukhulu becala, ubushushu obungavisisani, ubushushu obunobushushu, ukuxhathisa kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile, ukuqina kweoyile. Enye yefilimu eyintloko esisigxina, kodwa ukuchasana kwe-corona akulunganga.

Ixabiso lefilimu ye-polyester liphezulu, kwaye ubukhulu bayo buyi-0.12 mm. Ihlala isetyenziswa njengezinto zangaphandle zephakheji yokutya yokupakisha, kwaye inoshicilelo oluhle. Ukongeza, ifilimu ye-polyester ihlala isetyenziswa njengokuprinta kunye nokupakisha izidlo ezinjalo kwifilimu yoKhuseleko lweNdalo, ifilimu ye-Pety, kwaye isetyenziswa ngokubanzi kwi-miltiberm emhlophe, kwaye isetyenziswa ngokubanzi kumashishini anjengeeplani ze-fiber, kwaye iprinta, kunye neyeza kunye nezempilo.

Ifilimu ye-nylon (ony)

Igama lekhemikhali le-nylon yi-Polyamide (PA). Okwangoku, zininzi iintlobo ze-nylon ezivelisayo, kwaye ezona zinto ziphambili zisetyenziselwa ukuvelisa iifilimu yi-NYLOLO 6, NYLOLO 66, njl. Ukuchasana nobushushu, ukumelana kweoyile, ukumelana kweoyile kunye nokunganyangeki kweoyile kunye nokuchasana kweoyile. Ukunganyangeki kakuhle kunye nokuhlonipha ukumelana, ukuthambisa iipropathi ezingalunganga, kodwa ukufunyanwa kobunzima obuphezulu, ukutya okuphezulu, ukutya okuthotyiweyo, ukutya okuthengiswayo, njl njl.

Ifilimu ye-Polyproplene (CPP)

Ngokungafaniyo nenkqubo yefilimu ye-BiaicyPropylene yefilimu, ifilimu ye-volyproplene ifilimu (CPP) yifilimu engeyiyo eyoluliweyo eveliswe kukunyibilika. Iphawuleka ngesantya esikhawulezayo semveliso, ukukhupha okuphezulu, ukungafihli ifilimu elungileyo, i-gloss, i-physed phuthi iyunifomu, kunye nokulinganisa okuhle kwezakhiwo ezahlukeneyo. Kuba kuyifilimu ekhutshiweyo, umsebenzi wokulandela onjengokuprinta kunye nokudibanisa kufanelekile kakhulu. I-CPP isetyenziswa ngokubanzi ekupakisheni ii-lengs, iintyatyambo, ukutya kunye neemfuno zemihla ngemihla.

Ifilimu ye-aluminium

Ifilimu ye-alcoind ineempawu zombini zefilimu zeplastiki kunye neempawu zentsimbi. Indima ye-Aluminium yokubeka kumphezulu wefilimu kukukhusela ukukhanya kunye nokukhusela imitha ye-ultraviolet, kodwa iphucula ukuqaqamba kwefilimu. Ke ngoko, ifilimu ye-Atumin isetyenziswe ngokubanzi kwiphakheji yokudibanisa, ikakhulu isetyenziswa kwipakethi yowomileyo kunye nekhukuliseka yokutya okunjengeebhiskithi, kunye nokupakishwa kwangaphandle kwamayeza kunye ne-cosmetics.

IXESHA LOKUQALA: UJUL-19-2023