Lolu hlu lwamagama luhlanganisa amagama abalulekile ahlobene nezikhwama zokupakisha eziguquguqukayo nezinto zokwakha, egqamisa izingxenye ezahlukahlukene, izakhiwo, nezinqubo ezihilelekile ekukhiqizeni nasekusetshenzisweni kwazo. Ukuqonda le migomo kungasiza ekukhetheni nasekuklanyweni kwezixazululo ezisebenzayo zokupakisha.

Nali uhlu lwamagama ajwayelekile ahlobene nezikhwama zokupakisha eziguquguqukayo nezinto zokwakha:

1.Ukunamathela:Into esetshenziselwa ukuhlanganisa izinto ndawonye, ezivame ukusetshenziswa kumafilimu anezingqimba eziningi kanye nezikhwama.

2.I-Adhesive Lamination

Inqubo ye-laminating lapho izingqimba zomuntu ngamunye zezinto zokupakisha zihlanganiswe komunye nomunye nge-adhesive.

3.AL - Icwecwe le-Aluminium

Igeji elincanyana (ama-microns angu-6-12) i-aluminium foil elayishwe kumafilimu epulasitiki ukuze inikeze ubuningi bezinto zokuvimbela umoya-mpilo, iphunga kanye nokuvimbela umhwamuko wamanzi. Yize iyisivimbeli esingcono kakhulu, siya ngokuya sithathelwa indawo amafilimu enziwe ngensimbi, (bona i-MET-PET, MET-OPP ne-VMPT) ngenxa yezindleko.

4.Isithiyo

I-Barrier Properties: Ikhono lempahla yokumelana nokungena kwamagesi, umswakama, nokukhanya, okubalulekile ekwandiseni isikhathi seshelufu semikhiqizo epakishiwe.

5.I-Biodegradable:Izinto ezingahle zehle ngokwemvelo zibe izingxenye ezingenabuthi endaweni ezungezile.

6.CPP

Ifilimu ye-Polypropylene. Ngokungafani ne-OPP, iyavaleka ukushisa, kodwa emazingeni okushisa aphakeme kakhulu kune-LDPE, ngaleyo ndlela isetshenziswa njengesendlalelo sophawu lokushisa ekupakisheni okunamandla okuphindisela. Nokho, ayiqini njengefilimu ye-OPP.

7.COF

I-coefficient of friction, isilinganiso "sokushelela" kwamafilimu epulasitiki namalayini. Izilinganiso zivame ukwenziwa phezulu kwefilimu kuya phezulu kwefilimu. Ukulinganisa kungenziwa nakwezinye izindawo, kodwa akunconyiwe, ngoba amanani e-COF angahlanekezelwa ukwehluka kokuqedwa kwendawo kanye nokungcoliswa endaweni yokuhlola.

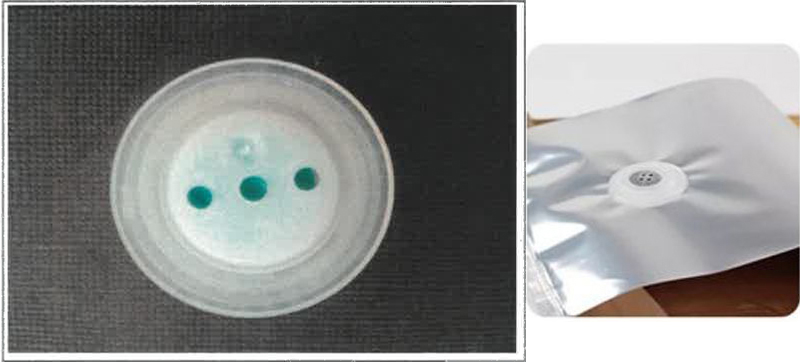

8.Ivalve yekhofi

I-valve yokukhulula ingcindezi yengezwe ezikhwameni zekhofi ukuvumela umoya wemvelo ongafuneki ukuthi ukhiphe umoya kuyilapho kugcinwa ubusha bekhofi. Ibizwa nangokuthi i-valve yephunga njengoba ikuvumela ukuthi uhogele umkhiqizo ngevalvu.

9.Die-Cut Pouch

Isikhwama esakhiwe esinama-contour side seal ebese sidlula ku-die-punch ukuze kunciphe into evalekile eningi, eshiya idizayini yokugcina yesikhwama esiyikhonkolo futhi enomumo. Ingafezwa ngazo zombili izinhlobo zesikhwama sokuma nesomcamelo.

10.Doy Pack (Doyen)

Isikhwama sokuma esinama-seal ezinhlangothini zombili naseduze kwe-gusset engezansi. Ngo-1962, u-Louis Doyen wasungula futhi wanikeza ilungelo lobunikazi isaka lokuqala elithambile elinephansi elivuthelwe elibizwa ngokuthi i-Doy pack. Nakuba lokhu kuhlanganiswa okusha bekungeyona impumelelo esheshayo obekulindelwe, kuyadlondlobala namuhla njengoba ilungelo lobunikazi selingenile esizindeni somphakathi. Futhi kupelwe - Doypak, Doypac, Doy pak, Doy pac.

11.I-Ethylene Vinyl Alcohol (EVOH):Ipulasitiki enezithiyo eziphezulu evame ukusetshenziswa kumafilimu anezingqimba eziningi ukuze inikeze ukuvikelwa okuhle kakhulu kwesithiyo segesi

12. Ukupakisha Okuguquguqukayo:Ukupakishwa okwenziwe ngezinto ezingagoba kalula, zisonteke, noma zigoqwe, ngokuvamile kufaka phakathi izikhwama, izikhwama, namafilimu.

13.Gravure Printing

(I-Rotogravure). Ngokuphrinta kwe-gravure isithombe siqoshwa phezu kwepuleti lensimbi, indawo enamathiselwe igcwaliswa ngoyinki, bese ipuleti lizungeziswa kusilinda esidlulisela isithombe kufilimu noma kwezinye izinto. I-Gravure ifushanisiwe ukusuka ku-Rotogravure.

14.I-Gusset

Ukugoqa ohlangothini noma phansi kwesikhwama, okusivumela ukuthi sikhule lapho okuqukethwe kufakwa

15.HDPE

Ukuminyana okuphezulu, (0.95-0.965) i-polyethylene. Le ngxenye inokuqina okuphezulu kakhulu, ukumelana nezinga lokushisa okuphezulu kanye nezakhiwo ezingcono kakhulu zokuvimbela umhwamuko wamanzi kune-LDPE, nakuba iyi-hazier kakhulu.

16.Heat seal Amandla

Amandla ophawu lokushisa akalwa ngemva kokuba uphawu lupholile.

17.Laser Amaphuzu

Ukusetshenziswa kokukhanya kokukhanya okunamandla aphezulu ukusika kancane into emugqeni oqondile noma amaphethini amumo. Le nqubo isetshenziselwa ukunikeza isici esivuleka kalula ezinhlotsheni ezihlukahlukene zezinto zokupakisha eziguquguqukayo.

18.LDPE

Ukuminyana okuphansi, (0.92-0.934) i-polyethylene. Isetshenziselwa ikakhulukazi ikhono lokuvala ukushisa kanye nenqwaba emaphaketheni.

19. Ifilimu ene-Laminated:Into eyinhlanganisela eyenziwe ngezingqimba ezimbili noma ngaphezulu zamafilimu ahlukene, enikeza izici ezithuthukisiwe zokuvimbela nokuqina.

20.MDPE

Ukuminyana okuphakathi, (0.934-0.95) i-polyethylene. Inokuqina okuphezulu, indawo ephakeme yokuncibilika kanye nezakhiwo ezingcono zokuvimbela umhwamuko wamanzi.

21.MET-OPP

Ifilimu ye-OPP eyenziwe ngensimbi. Inazo zonke izici ezinhle zefilimu ye-OPP, kanye nezakhiwo ezithuthukisiwe kakhulu zokwenza umoya-mpilo kanye nezivimbelo zomhwamuko wamanzi, (kodwa hhayi ezinhle njenge-MET-PET).

22.Ifilimu Yezingqimba Eziningi:Ifilimu elakhiwe ngezingqimba eziningana zezinto ezihlukene, ngayinye inikela ngezici ezithile njengamandla, umgoqo, nokuvaleleka.

23.Mylar:Igama lomkhiqizo lohlobo lwefilimu ye-polyester elaziwa ngamandla ayo, ukuqina, kanye nezakhiwo zokuvimbela.

24.NY - Inayiloni

Izinhlayiya ze-Polyamide, ezinamaphoyinti aphezulu kakhulu ancibilikayo, ukucaca okuhle kakhulu nokuqina. Izinhlobo ezimbili zisetshenziselwa amafilimu - inayiloni-6 kanye inayiloni-66. Lesi sakamuva sinezinga lokushisa eliphakeme kakhulu lokuncibilika, ngaleyo ndlela ukumelana nokushisa okungcono, kodwa okokuqala kulula ukusetshenzwa, futhi kushibhile. Zombili zinezici ezinhle zokuvimbela umoya-mpilo kanye nephunga elimnandi, kodwa ziyizithiyo ezingezinhle kumhwamuko wamanzi.

I-25.OPP - I-Oriented PP (i-polypropylene) Ifilimu

Ifilimu eqinile, ecace kakhulu, kodwa engavaleki ukushisa. Ivamise ukuhlanganiswa namanye amafilimu, (afana ne-LDPE) ukuze kuvalekeke ukushisa. Ingagcotshwa nge-PVDC (i-polyvinylidene chloride), noma ifakwe insimbi ukuze uthole izakhiwo ezingcono kakhulu zokuvimbela.

26.OTR - Izinga Lokudluliswa Kweoksijini

I-OTR yezinto zepulasitiki ihlukahluka kakhulu ngomswakama; ngakho-ke idinga ukucaciswa. Izimo ezijwayelekile zokuhlolwa ngu-0, 60 noma 100% umswakama ohlobene. Amayunithi angu-cc./100 amayintshi skwele/amahora angu-24, (noma cc/skwele imitha/24 Hrs.) (cc = cubic centimeters)

27.PET - I-Polyester, (I-Polyethylene Terephthalate)

I-polymer eqinile, imelana nezinga lokushisa. Ifilimu ye-PET ene-Bi-axially oriented isetshenziswa kuma-laminates ukupakisha, lapho inikeza amandla, ukuqina nokumelana nokushisa. Ivamise ukuhlanganiswa namanye amafilimu ukuze kucishwe ukushisa kanye nezakhiwo zokuvimbela ezithuthukisiwe.

28.PP – Polypropylene

Inephuzu lokuncibilika eliphakeme kakhulu, ngaleyo ndlela ukumelana nokushisa okungcono kune-PE. Izinhlobo ezimbili zamafilimu e-PP zisetshenziselwa ukupakishwa: i-cast, (bona i-CAPP) kanye ne-oriented (bona i-OPP).

29.Isikhwama:Uhlobo lokupakisha oluguquguqukayo oludizayinelwe ukubamba imikhiqizo, ngokuvamile enokhakhakhayi oluvalwe phezulu kanye nesikhala sokufinyelela kalula.

30.PVDC - I-Polyvinylidene Chloride

I-oksijini enhle kakhulu nomgoqo womhwamuko wamanzi, kodwa ongakhipheki, ngakho-ke itholakala ngokuyinhloko njengesembozo sokuthuthukisa izakhiwo zokuvimbela amanye amafilimu epulasitiki, (njenge-OPP ne-PET) ukuze afakwe. I-PVDC ehlanganiswe ne-'saran' ehlanganisiwe iyafana

31. Ukulawulwa Kwekhwalithi:Izinqubo nezinyathelo ezibekiwe zokuqinisekisa ukuthi ukupakishwa kuhlangabezana namazinga athile okusebenza nokuphepha.

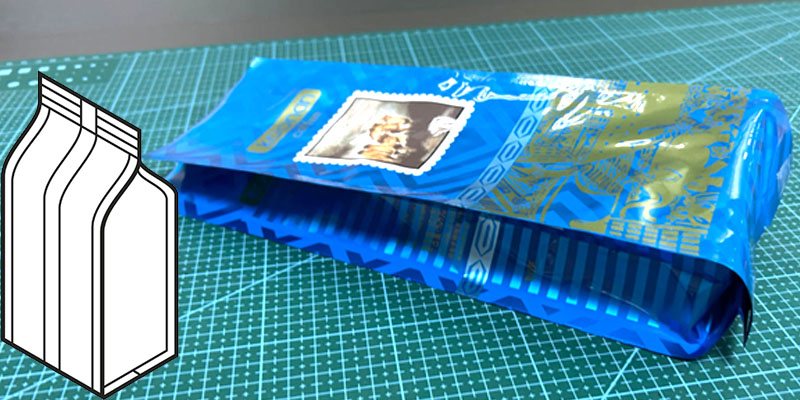

32.I-Quad Seal Bag:Isikhwama se-quad seal siwuhlobo lwamaphakheji aguquguqukayo anezimpawu ezine—ezimbili eziqondile nezimbili ezivundlile—ezidala izimpawu zamakhona ohlangothini ngalunye. Lo mklamo usiza isikhwama ukuthi sime siqondile, sisenze sifaneleke kakhulu imikhiqizo yokupakisha ezuzayo ekwethulweni nasekuzinzeni, njengama-snacks, ikhofi, ukudla kwezilwane ezifuywayo, nokuningi.

33.Buyisa

Ukucutshungulwa okushisayo noma ukupheka ukudla okupakishiwe noma eminye imikhiqizo emkhunjini onomfutho ngezinjongo zokuvala inzalo okuqukethwe ukuze kugcinwe ukusha isikhathi eside sokugcina. Izikhwama ze-retort zenziwe ngezinto ezifanele amazinga okushisa aphezulu enqubo yokubuyisela kabusha, ngokuvamile azungeze u-121° C.

34. I-Resin:Into eqinile noma ebonakala kakhulu etholakala ezitshalweni noma izinto zokwenziwa, ezisetshenziselwa ukwakha amapulasitiki.

35.Roll Stock

Kushiwo nganoma iyiphi impahla yokupakisha eguquguqukayo esesimweni sokugoqwa.

36.Rotogravure Printing - (Gravure)

Ngokuphrinta kwe-gravure isithombe siqoshwa phezu kwepuleti lensimbi, indawo enamathiselwe igcwaliswa ngoyinki, bese ipuleti lizungeziswa kusilinda esidlulisela isithombe kufilimu noma kwezinye izinto. I-Gravure ifushanisiwe ukusuka ku-Rotogravure

37.Isikhwama Sokunamathela

Isikhwama sokupakisha esiguquguqukayo esincane esivame ukusetshenziselwa ukupakisha izingxube zesiphuzo sempushana esetshenziswa kanye njengeziphuzo zezithelo, ikhofi elisheshayo netiye noshukela nemikhiqizo ekhilimu.

38. Isendlalelo se-Sealant:Isendlalelo esingaphakathi kwefilimu enezingqimba eziningi enikeza amandla okwenza izimpawu ngesikhathi sezinqubo zokupakisha.

39.Nciphisa Ifilimu:Ifilimu yepulasitiki eshwabene iqine phezu komkhiqizo lapho kufakwa ukushisa, ngokuvamile isetshenziswa njengenketho yesibili yokupakisha.

40.Amandla Okuqina:Ukumelana kwempahla ekubhodlokeni ngaphansi kwe-tension, impahla ebalulekile yokuqina kwezikhwama eziguquguqukayo.

41.VMPET - Vacuum Metallised PET Film

Inazo zonke izakhiwo ezinhle zefilimu ye-PET, kanye nezakhiwo ezithuthukisiwe kakhulu zokwenza umoya-mpilo kanye nezivimbelo zomhwamuko wamanzi.

42. Ukupakishwa kweVacuum:Indlela yokupakisha esusa umoya esikhwameni ukuze yelule ubusha nempilo yeshelufu.

43.WVTR - Izinga Lokudluliswa Kwemphunga Wamanzi

ngokuvamile kukalwa ngo-100% womswakamo ohlobene, ovezwa ngamagremu/100 amayintshi square/amahora angu-24, (noma amagremu/isikwele imitha/24 Hrs.) Bheka i-MVTR.

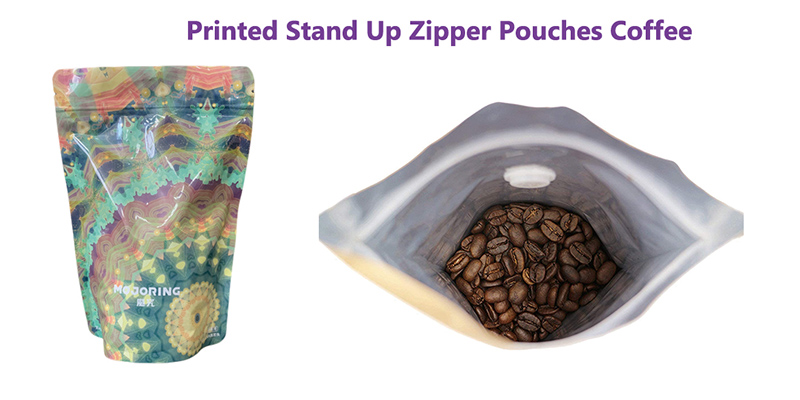

44.Isikhwama Soziphu

Isikhwama esivalekayo noma esivalekayo esikhiqizwe ngethrekhi yepulasitiki lapho izingxenye ezimbili zepulasitiki zihlangana ukuze zinikeze indlela evumela ukuphinda kuvaleke kuphakheji eguquguqukayo.

Isikhathi sokuthumela: Jul-26-2024